Magnetically coupled pumps for maximum operational reliability

More and more often, magnetic drives are the solution of choice in pump construction. They ensure that the pump is hermetically sealed from the drive. Leak-free operation becomes possible with a minimum of maintenance. This also prevents the environmental impact caused by materials leaking out during pumping processes.

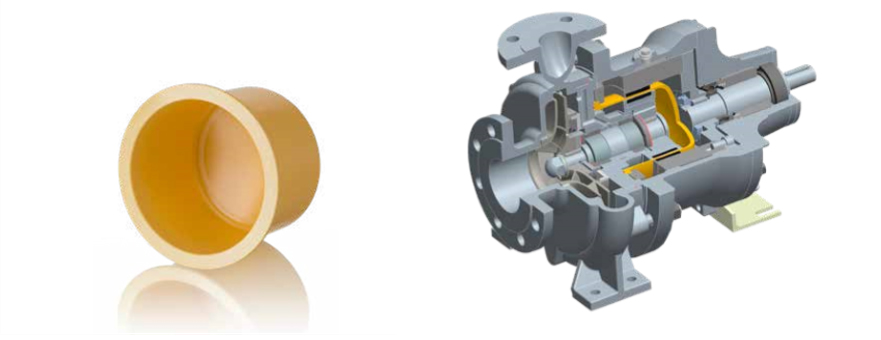

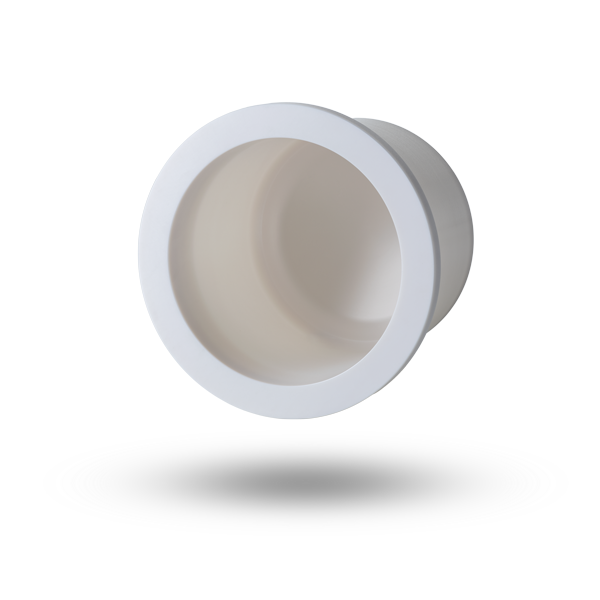

A magnetic drive pump combines conventional pump hydraulics with a drive system, generally involving a permanent magnet. This system uses the pull and push forces between permanent magnets in the two sides of the clutch to transmit torque with no contact and without slippage. The containment shell, which separates the product space from the surroundings, is placed between the two halves of the clutch, which are equipped with magnets.

Magnetic drive pumps are used especially when pumping toxic, odorous, or otherwise hazardous materials, as the containment shell hermetically seals off the substance from the surrounding environment.

The right choice with KYOCERA Fineceramics Europe

Non-metallic containment shells, especially those made of technical ceramics, have been used for a wide array of series applications by pump manufacturer Klaus Union for over 25 years now. Klaus Union looks back: “We were looking for a material that would be able to withstand high pressure, be highly resistant to corrosion, and stand up to temperatures of up to 450°C all at once. We found what we were looking for in a company called FRIATEC GmbH.”

Dickow Pumpen has also been using ceramic containment shells in its pumps since 1987. “At the start, we couldn’t replace metallic containment shells one to one with ceramic ones. Getting there took extensive development and design work,” Dickow explains. Because there were safety concerns regarding how pressure-resistant zirconium oxide would be, the first containment shells were made with very thick walls. Thicker walls meant a greater distance between magnets compared to the standard design, which in turn brought lower transmission performance. Numerical load calculations and FEM analyses of various different designs under given load and boundary conditions showed that while the wall thickness of the cylindrical part of the containment shell is a factor in the maximum pressure load, it is not the key factor. The design and configuration of the transitions to the dished bottom and flange attachment are much more important. Optimum design in these areas allowed for thinner walls even as pressure resistance remained stable, along with lower-cost dimensioning of the magnets used. This resulted in complete exchangeability.

Only the ceramic containment shell makes high energy efficiency possible

Another aspect of the ceramics is that containment shells made of FZM zirconium oxide are not electrically conductive, which means using them does not generate any eddy current losses. No heat is transferred to the pumped product, so even applications with a higher gas proportion and substances that are close to the boiling point, such as in the case of liquid gas applications, can be pumped safely. At the same time, energy costs are reduced because eliminating eddy current losses in the containment shell reduces the shaft power required. This means smaller electric motors can be installed, and the power input can be reduced by 10–15%.

Klaus Union offers the following example: “We subsequently modified the first of three identical pumps for our customer in such a way that both power consumption and feed-in volume for the purpose of bearing lubrication and cooling, which is necessary in the case of metallic containment shells, were significantly reduced. The solution here is an SLM NVO magnetic drive centrifugal pump equipped with our biggest hydraulics (400-400-500). The metallic containment shell was replaced with a non-metallic one made of technical ceramic. Using this new containment shell material eliminates eddy currents, so power consumption was reduced by 20 kW and the feed-in volume of clean material went down by nearly 90%.”

Ceramic containment shells open up a wide range of applications for magnetically coupled pumps

These days, ceramic containment shells are an integral element of the modular Klaus Union system. Says Klaus Union: “Our pumps have a universal casing cover, which means containment shells are simple and secure to install and replace.”

Current challenges include applications with ever higher pressures, temperatures, and performance even as efficiency is enhanced. Kyocera has succeeded in developing a new material that accommodates these more stringent requirements. FZM+ zirconium oxide can cover test pressures of up to 95 bar for a temperature range of -200°C to > +450°C. “It’s a new milestone for us to be able to reach pressure levels of up to PN 63 using shells made from Kyocera’s improved zirconium oxide,” Klaus Union explains.