Your partner for cutting hard and brittle materials

Slicing Service

With state-of-the-art multi-wire sawing technology and over 25 years of experience in the production of silicon wafers, KYOCERA Fineceramics Europe GmbH offers high-precision sawing services for a wide range of materials. These include quartz glass, glass ceramics, crystals, oxide and non-oxide ceramics, alloys, composites and natural stones.

Our expertise includes materials such as quartz glass, Zerodur®, silicon and calcium fluoride crystals as well as ceramic products made of alumina, zirconia, silicon nitride and silicon-infiltrated silicon carbide. We also process ferrites, magnesium titanates, refractory metals such as tungsten and molybdenum as well as innovative composite materials such as silicon aluminium, aluminium graphite and carbon fibre-reinforced plastics.

We cut these materials into high-precision slices on a micrometre scale with minimal cutting loss. Our priority is the highest quality and responsible handling of your materials. Together we develop improved solutions for your innovative products.

The biggest advantages of wire sawing are

- Edge lengths/diameters from 4 mm to 500 mm

- Thickness from 0.14 mm to 30 mm

- Various materials

- Various formats

- Very low cutting loss

- Very low edge defects and sub-surface damage

You are interested in our products or have a specific project enquiry?

25 years of experience in cutting hard and brittle materials

Wire sawing technology

The so called “wire sawing“ process is used to slice materials and it is actually a lapping process while using free abrasives. During the process, a very thin steel wire is drawn off at high speed over grooved wire guiding rollers (red). This causes a fast moving wire web of up to 3500 horizontally parallel wire loops. This wire web is continuously wetted with a sawing fluid, called slurry. This slurry consists of a carrier liquid and abrasive particles. The material to be sawn is slowly driven vertically through the wire web over several hours. The wire wetted by the slurry transports the particles into the sawing gap, where they have an abrasive effect. Thus, up to thousands of slices of your material can be cut in one cutting operation.

The wire sawing process reaches higher accuracies and material usage and less sawing damage and edge defects compared to conventional sawing technologies and shows therefore very high cost- and material-efficiency.

Many hard and brittle materials are cuttable

Material capabilities

Our technologies allow the cutting of a wide variety of hard and brittle materials. In recent years, we have processed a wide spectrum of different materials:

(Non)oxide ceramics | Al2O3, silica, ZrO2, ferrite, SiSiC, SiC, Si3N4 |

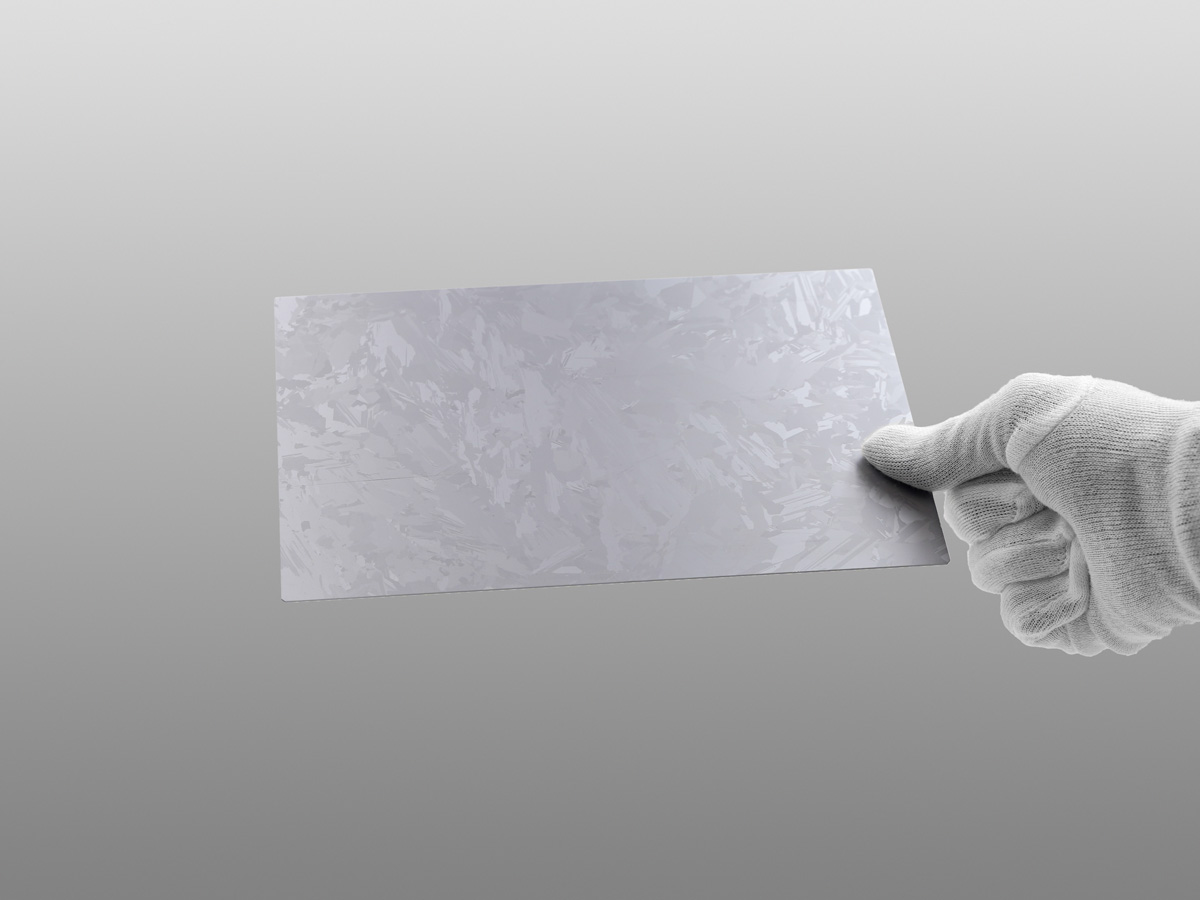

| (Quartz) glass | Quartz glass, Zerodur®, aluminosilicate glass, glass ceramics |

| Crystals | Si, quartz, CaF2, GaN, sapphire, SiC |

| Alloys | SiAl, MoCu, WCu, W, Mo, MgTi |

| Composite materials | CFK, AlG |

| Natural stone | Marble, granite |

We offer comprehensive and well-founded process, product and material know-how. Processes are individually optimized for your material from the first test cut to a series production.

Various geometries are feasible

Formats

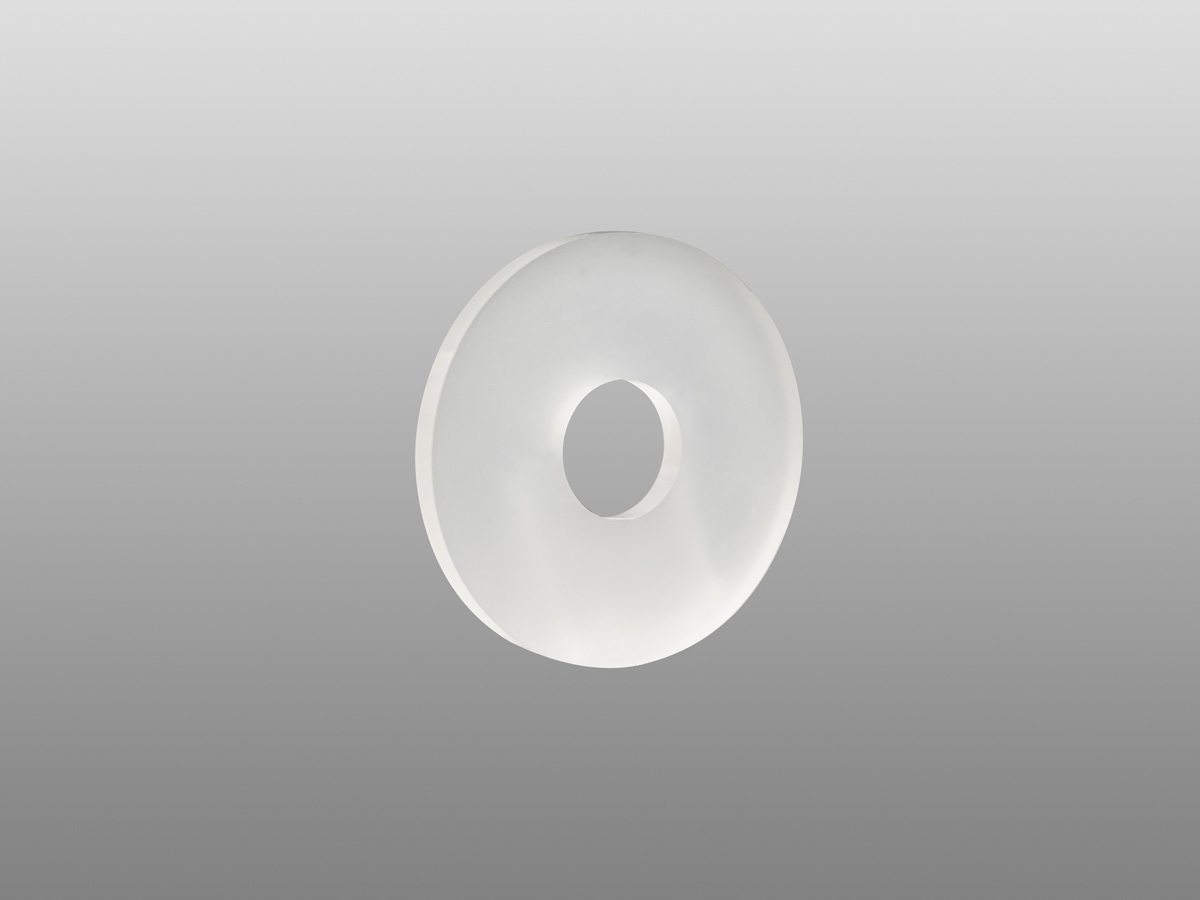

The possible format spectrum of your materials varies from cuboids to cylinders and hollow cylinders, tubes, round rods, ingots, boules, billets, blanks, bars and crystals.

Our wire saws allow us to cut up to 4 x 500 mm material length in one single cut, depending on the cross-section of your material.

| Ingots and cuboids (also bars, blanks) | Cross section < 300 x < 300 mm² Multiple lengths up to 250 mm |

| Large hollow cylinders (also tubes, billets) | Inner diameter > 290 mm Outer diameter < 400 mm Length < 500 mm |

Cylinders and hollow cylinders | Outer diameter < 300 mm Length < 500 mm |

Crystals (also boules) | Outer diameter < 210 mm Length < 500 mm |

Large formats | Cut area < 750 x < 500 mm² |

Quality made in Geramany

Manufacturing precision for multi-wire sawing

We achieve a cutting loss of less than 0.15 mm, using wires with a thickness of 0.10 – 0.12 mm. This enables a very high utilisation of your valuable material . The multi-wire sawing technology allows the production of highly precise discs with thicknesses varying from 0.14 to 30 mm and with the following product parameters:

| Thicknesses | 0.14 – 30 mm |

Thickness variation* | +/- 20 µm |

Flatness* | < 100 µm |

Parallelism* | < 100 µm |

Roughness Rz | 4 – 5 µm |

Roughness Ra | < 0.5 µm |

| Depth damage | 8 – 9 µm |

* depending on initial format

The excellent surface quality of the cut surfaces often eliminates the need for subsequent surface grinding or lapping. This leads to an additional cost advantage for our customers.

Your partner for cutting hard and brittle materials

You have the product idea - KYOCERA Fineceramics Europe GmbH realises it, from initial development to series production.

As an expert in cutting technologies for brittle-hard materials, Kyocera offers solutions from a single source - from consulting to production and packaging. Our flexible and efficient processes are ideal for industries such as semiconductors, automotive, medical technology, optics, aerospace, consumer electronics and photovoltaics.

Thanks to years of experience, we develop precise processes for cutting, cleaning, drying and packaging - always with the highest quality standards in the µm range. Our partnership-based customer relationships drive innovation and guarantee marketable solutions.

Benefit from our technological expertise, customised approaches and the reliability of a strong partner.

Contact us - your success is what drives us.