Technical ceramics for the aviation and aerospace industry

Kyocera demonstrates how versatile advanced ceramics are with solutions from high-performance ceramics for the aviation and aerospace industry. Those must of course meet high standards of safety, reliability, service life and precision. High-quality monolithic components in particular offer excellent prospects for use in the aviation and aerospace industry. Due to its lightweight nature, high-performance ceramic components can also contribute to cost savings, without having to sacrifice the highest quality and outstanding product properties. We are always looking for innovative solutions and new areas of application. As a result, we are closely involved with our customers creating an optimal product made of technical ceramics. We would gladly develop this together with you and offer you our professional support, from idea to finished components.

You are interested in our products or have a specific project enquiry?

Space & Astronomy Materials

Fine Cordierite (CO720)

Fine Cordierite is an extremely low thermal expansion ceramic, which was developed over two decades ago. We have been constantly improving its characteristics.

Characteristics

- Minimal temperature deformation due to unique material composition with an extremely low thermal expansion rate

- Approx. 70% weight reduction when compared to low CTE glass* with a slim ribbed, high rigidity design structure

- Rapid process time even for complex designs due to good machinability

* based on Kyocera's research

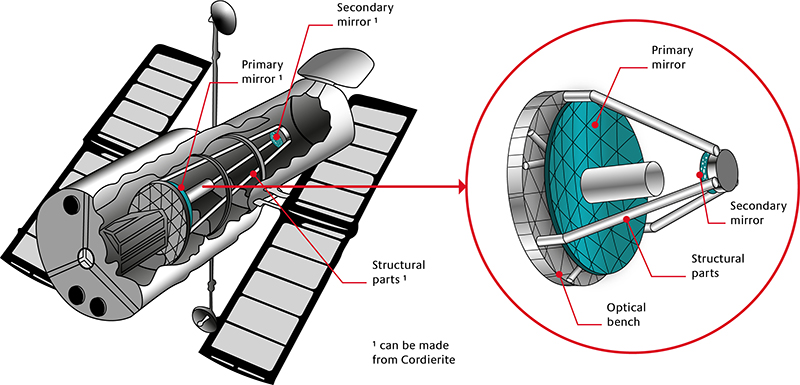

Structural parts made of ceramics in a satellite

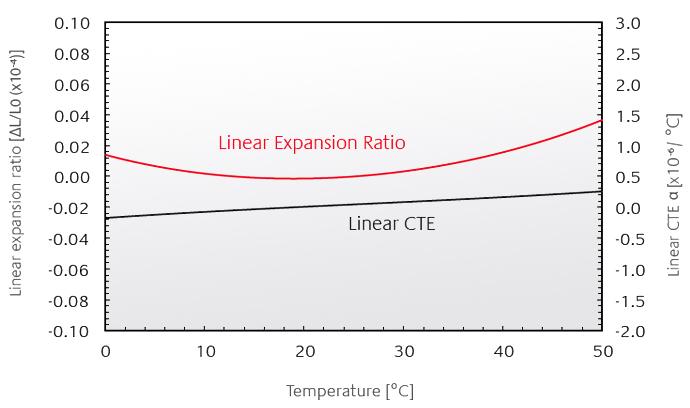

Temperature dependency graph Fine Cordierite CO720

Material characteristics comparison with Low CTE glass

| Low CTE glass | Fine Cordierite CO720 | |

|---|---|---|

| Density [g/cm3] | 2.53 | 2.55 |

| CTE** [ppm/K] | 0.02 | 0.02 |

| Elasticity modulus [GPa] | 90 | 145 |

| Specific rigidity | 36 | 57 |

The values are typical material properties and may vary according to product configuration and manufacturing process.

** temperature dependency graph

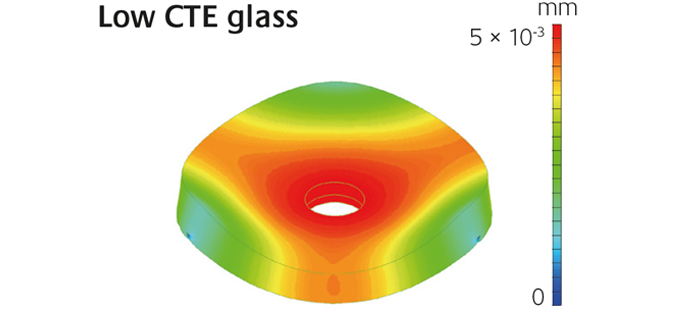

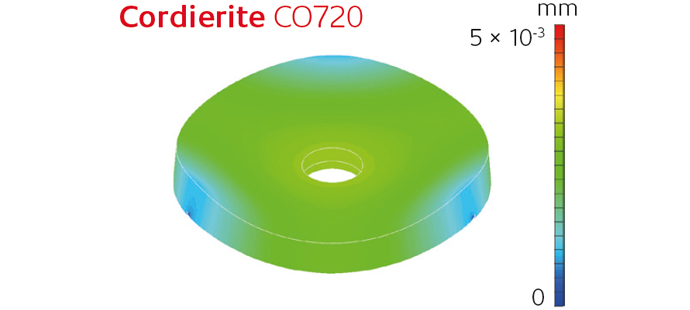

Displacement map***

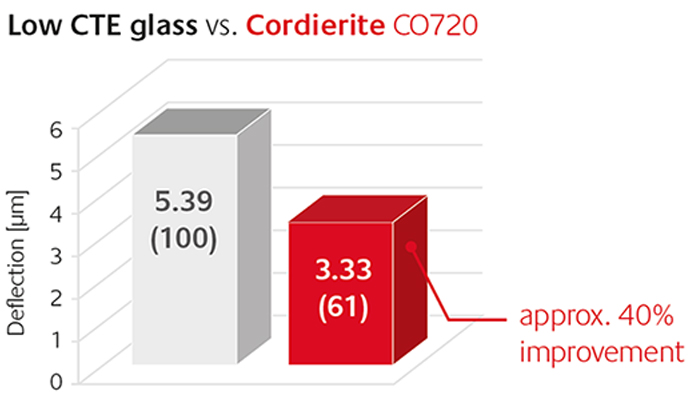

3-point supported deflection***

Comparison conditions:

- Product size: Ø1020 x 120mm (rib structure)

- Supported points: outside 3 points

- Load: self-weight

*** based on Kyocera's research

Silicon-infiltrated silicon carbide (SiSiC)

Proprietary joining and manufacturing technology for SiSiC enables complex, high precision components with unique design features:

- Hidden internal cavities possible (e.g. cooling channels)

- Complex and fine detailed structures below 1 mm achievable

- Large-scale parts monolithically up to 950 x 950 x 650 mm and larger via proprietary joining technologies

- High strength, extreme stiffness and reliability components at lowest weight

- Joining areas with identical material properties, such as Young's modulus and strength

Material properties

- Closed porosity for water and gas tightness requirements

- produced of ultra pure semi conductor grade material

- Extremely homogeneous material, even for large-scaled part

| StarCeram® Si SiSiC | |

| SiC | min. 85 wt% |

| Si | max. 15 wt% |

Sintered silicon carbide (SiC)

Excellent SSiC material properties enable applications up to 1600 °C

requiring high mechanical and chemical resistance

Material properties

- Excellent chemical resistance from basic to acidic materials allowing applications in harsh environments

- Large-scaled parts with outstanding high temperature performance answering the demanding needs of the aerospace industry

Chemical resistance

Material properties

| StarCeram® S SSiC | StarCeram® Si SiSiC | |

|---|---|---|

| Density [g/cm³] | 3.13 | 3.05 |

| Fracture strength RT [MPa] | 373 | 300 |

| Young’s modulus RT [GPa] | 395 | 380 |

| Thermal conductivity RT [W/mK] | 125 | 200 |

| CTE (RT -1,000C°) [x10-6K-1] | 4.5 | 4.0 |

| Resistivity RT [Ωm] | 104 | 10-2 |

| Thermal shock coefficient R1 [K] | 180 | 190 |

| Max. working temperature [°C] | 1,600 | 1,350 |

Alumina (Al2O3) and Zirconia (ZrO2)

Kyocera’s oxide ceramics display operational safety, reliability and long lifetime based on the following physical characteristics:

- Mechanical strength

- High chemical resistance

- Good thermal shock resistance at high and low temperatures

- Good thermal conductivity

- Excellent electrical resistance

- Low dielectric loss at high frequency

Brazed oxide ceramic-to-metal assemblies outreach the excellent properties of ceramics and metal. Ceramics show electrical insulation; metal components feature weldability. This advantageous combination enables a wide range of vacuum, high-voltage and high-pressure applications.

| Alumina F99.7 α-Al2O3 | Zirconia FZM ZrO2 MgO | |

|---|---|---|

| Purity [wt-%] | > 99.7 | > 99.7 |

| Apparent density [g/cm³] | ≥ 3.90 | ≥ 5.70 |

| Bending strength [N/mm² (MPa)] | 350 | 500 |

| Maximum operating temperature [°C] | 1,950 | 900 |

Space and Astronomy Applications

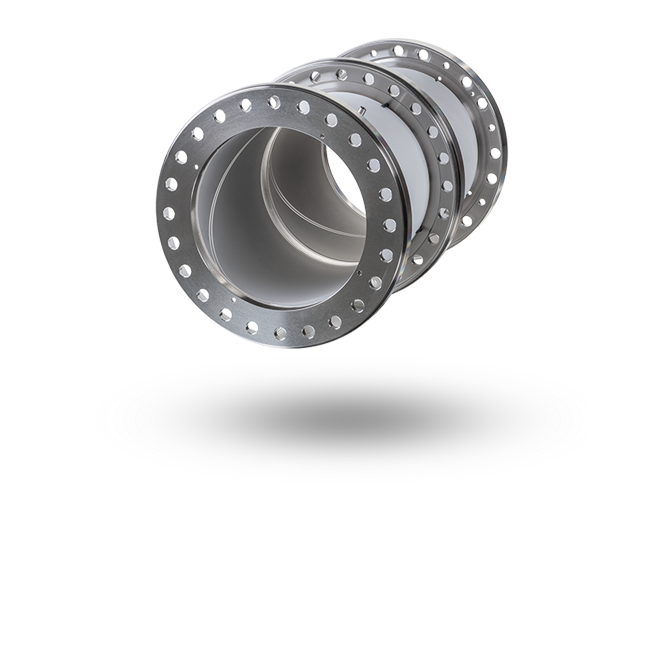

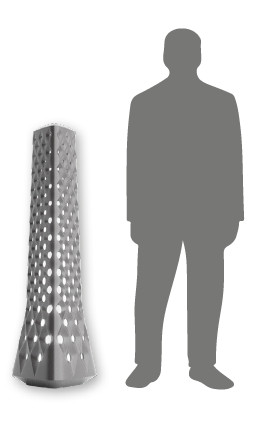

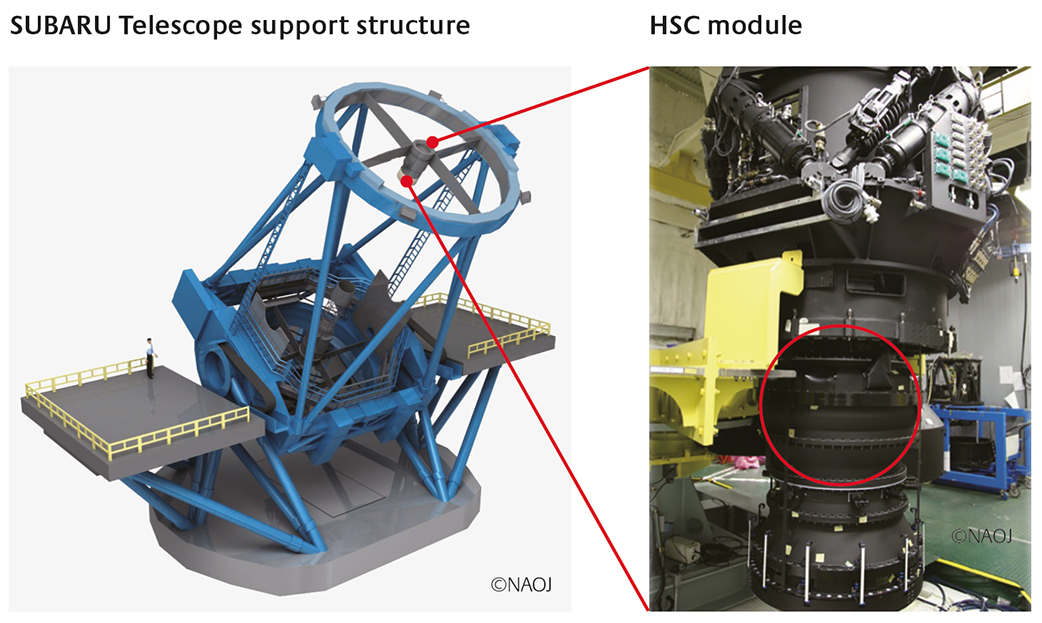

Camera lens spacer

Subaru Telescope is an 8.2-meter (320 in) optical-infrared flagship telescope operated by the National Astronomical Observatory of Japan (NAOJ), located at the Mauna Kea Observatory on Hawaii.

In 2012, when NAOJ installed a new super wide angle camera “Hyper Suprime-Cam (HSC)” into the SubaruTelescope, there were two design requirements for adaptive optics. One was to produce a larger lens aperture and the other was to reduce the lens' weight.

Kyocera’s Fine Cordierite was chosen as the best material to achieve the two design requirements for the lens support. Enabled by superior characteristics of Fine Cordierite a slim design was developed. This design features high material strength and rigidity to support the lens structure. Furthermore, it minimizes deformations caused by temperature fluctuations.

Fine Ceramics technology supporting space observation 13 billion light years away

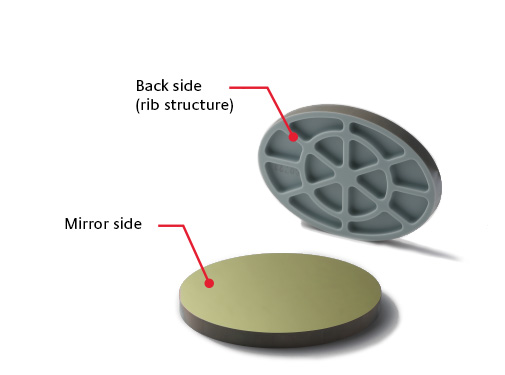

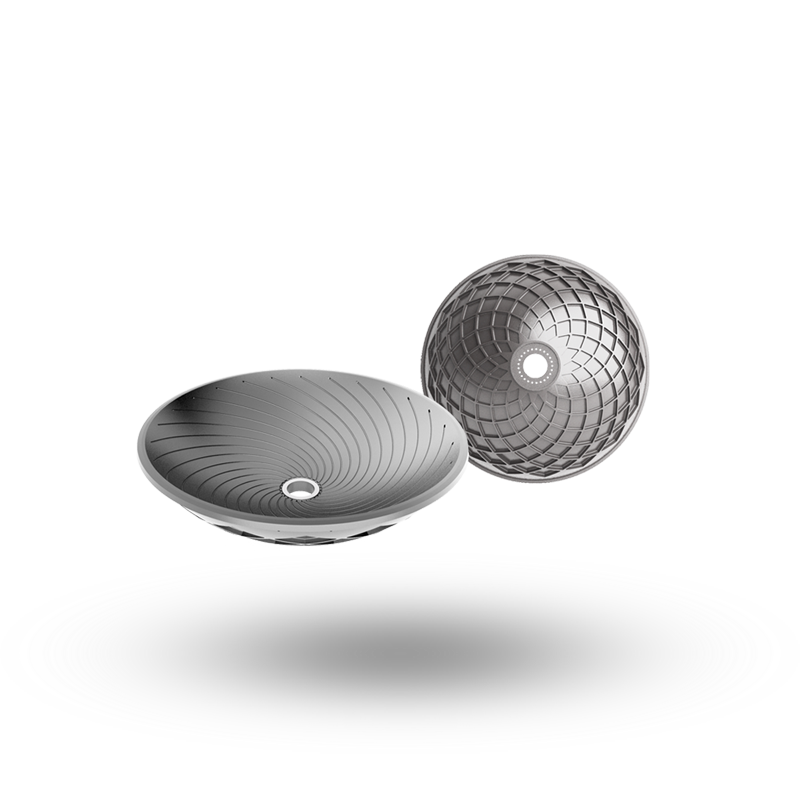

Optical systems including mirrors

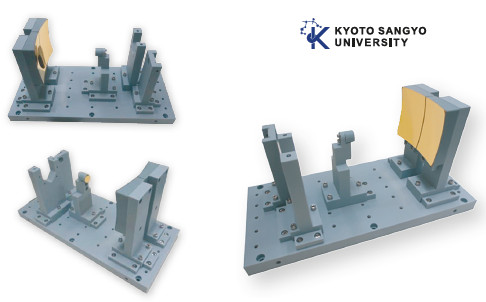

We have developed diffraction-limited off-axis reflective optical systems (mirrors, mirror holders, and optical benches) made entirely of Fine Cordierite materials, with Kyocera’s high accuracy assembling technology.

Fine Cordierite was applied because of its great “athermal property”. Relying on its monlithic nature, the optical performance does not degrade under varying temperature conditions. We processed this extremely low thermal expansion ceramic allowing Fine Cordierite mirrors coated with metal (Au), as seen in the pictures.

Additionally, larger Fine Cordierite mirrors of over 1 meter diameter, can be produced with a light weight design and the required surface roughness. Such structures are expected to be installed in large telescopes (30 meters) and space telescopes in the coming years.

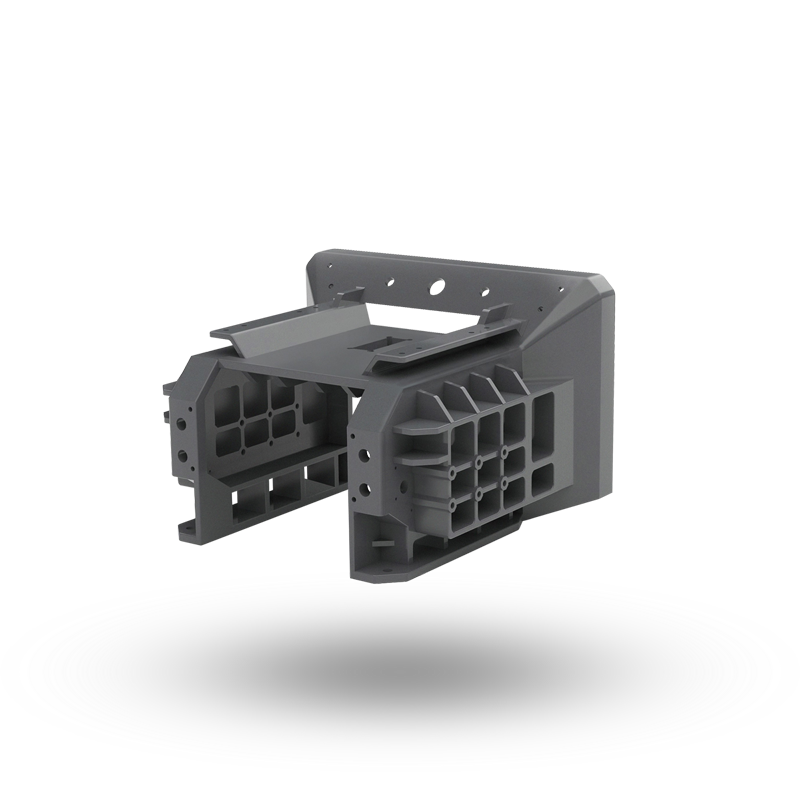

Camera housing made of F99.7 for aerospace industry

In-house 5-axis CNC machining supported by ultrasonic processing allows the manufacture of complex components such as camera housings. The permeability of ceramics for electromagnetic radiation takes effect in this type of application: the electromagnetic waves of the sensors inside the housing can pass through to the outside, while radar beams from outside are hardly reflected thus impeding detection of aircraft.

Insulators for ion thrusters

High electrical insulation and thermal strength of our F99.7 alumina material allow its application in of ion thruster components. Excellent performance in ultra-high vacuum is guaranteed by minimal desorption and leakage rate. When required, we combine ceramics with metals.

Customized parts

Low weight and high corrosion resistance combined with high mechanical strength make our ceramic materials perfectly suitable for space applications. We excel in specific solutions. Our years of experience as a manufacturer of customized and standard components guarantee superior solutions to accomplish a variety of tasks.