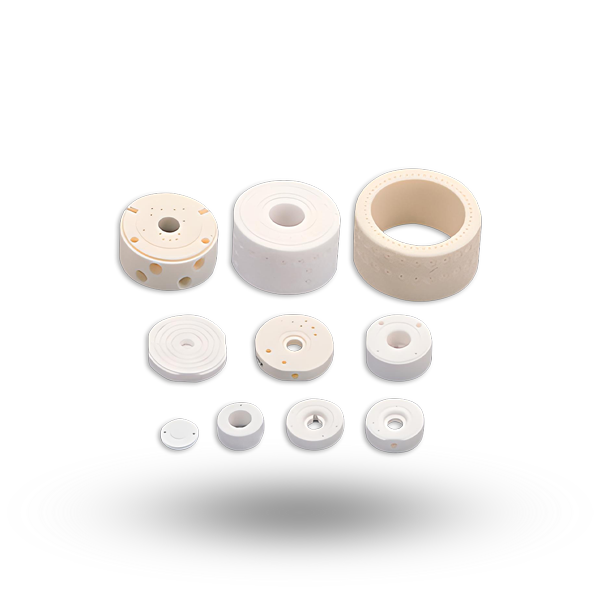

The right solution for every requirement

Abrasion-resistant, chemically resistant, and durable

Rotors and stators are indispensable components of electric motors and generators. They must withstand various stresses, including abrasion and chemical corrosion, to ensure high performance and long life. This is where Kyocera's ceramic rotors and stators come into play.

Rotors and stators are utilized in high-performance, high-pressure applications involving repetitive motions especially in analytical devices such as Liquid Chromatography (LC). In such applications, these components must endure significant stresses, including abrasion and chemical corrosion, to guarantee both high performance and longevity.

Kyocera's custom-designed alumina and zirconia rotors and stators offer significantly longer lifespans compared to metals, thanks to their superior material properties.

High abrasion resistance

Our stators and rotors made of technical ceramics are characterised by their high hardness and strength, contributing to their high abrasion resistance. These properties make them ideal for applications with a high stress level.

Chemical resistance

The chemical resistance of our ceramic stators and rotors ensures their reliability and long life, even in aggressive environments.

Durability

Our alumina and zirconia rotors and stators are durable and offer reliable performance thanks to their high abrasion and chemical resistance.

Premium surface quality

Thanks to the state of the art processing and long history, we can achieve premium surface roughness parameters.

Potential Applications

We have a long history of supplying custom-designed rotors and stators used in following applications:

- As switch valves used in Liquid Chromatography

- Vaccine development due to high chemical resistance of ceramics compared to metal.

- Components of electric motors and generators.

Our manufacturing capabilities include:

- Green machining, forming such as CIP, F-molding, pressing, injection molding, extrusion., 3D printing etc.

- Post sintering processing of both alumina and zirconia such as polishing, drilling, etc.,

Kyocera offers high-quality and durable solutions for electric motors and generators. tailored to your individual needs and requirements. Our advanced ceramics rotors and stators provide reliable performance and long life in demanding applications. Contact us today to learn more!