The right solution for every requirement

High-performance nozzles made from technical ceramics

Nozzles are an important component in many applications and machines, including welding equipment, blasting systems and cleaning machines. To ensure high efficiency and a long service life, they must be able to withstand considerable stress, including wear, corrosion and high temperatures. With their outstanding material properties, Kyocera technical ceramic nozzles fulfil these demanding requirements.

High wear resistance

Our nozzles are characterised by their high strength and hardness, which contributes to their very good wear resistance. This makes them ideal for applications with abrasive media.

Good chemical corrosion resistance

Nozzles made of high-performance ceramics offer excellent chemical corrosion resistance, making them ideal for applications in corrosive environments. This property, combined with high hardness and strength, ensures a long service life and reliable, consistently high performance.

Very good edge stability

Our technical ceramic nozzles have excellent edge stability, resulting in an extremely even spray cone. This property is particularly important for applications where an even distribution of liquids is required.

Good thermal shock resistance

Our high-performance ceramic nozzles are highly resistant to thermal shock, making them ideal for a wide range of applications with changing operating conditions.

High hardness and pressure resistance

Our nozzles made of high-performance ceramics are hard and pressure-resistant, which contributes to a long service life and reliable performance.

Variety of materials

We offer our customers a wide range of solutions tailored to their individual needs and requirements. In addition to silicon carbide and silicon nitride, our materials also include silicon infiltrated silicon carbide, zirconia, and alumina as well as aluminium titanate.

You are interested in our products or have a specific project enquiry?

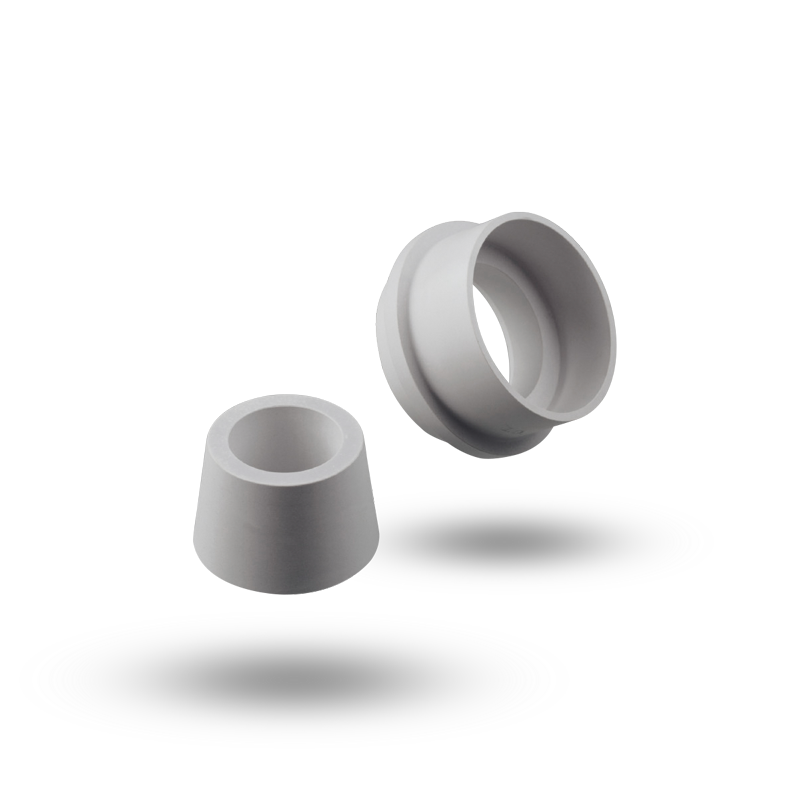

Gas nozzles

MIG/MAG gas nozzles are an essential part of the burner equipment and ensure stable gas coverage during the welding process. The choice of the right gas nozzle has a significant influence on the quality of the weld seam and process reliability. The use of high-performance ceramics from Kyocera significantly reduces the build-up of welding spatter, which increases the service life of the gas nozzle and extends maintenance intervals.

No cold welding compared to steel

Our silicon nitride gas nozzles have no cold welding compared to steel, which makes them ideal for MIG/MAG welding applications.

Low weld spatter adhesion

Thanks to their low spatter adhesion, our technical ceramic gas nozzles ensure smooth and efficient welding performance.

Nozzles, funnels and plugs

When it comes to dosing and filling melts and liquids in production, high precision and reliability are essential. Kyocera offers a wide range of nozzles, funnels and plugs made of technical ceramics that fulfil these requirements.

Outstanding mechanical material properties

Our nozzles, funnels and plugs made of high-performance ceramics show high hardness and strength, which guarantee a long service life and high efficiency.

Abrasion resistance

They also prevent metallic contamination in the compound, which is particularly important in the food and pharmaceutical industries.

Thermal stability

With excellent thermal shock behaviour, our products are ideal for applications where frequent temperature changes occur. Their thermal insulation ensures that the melt or liquid is kept at constant temperatures.

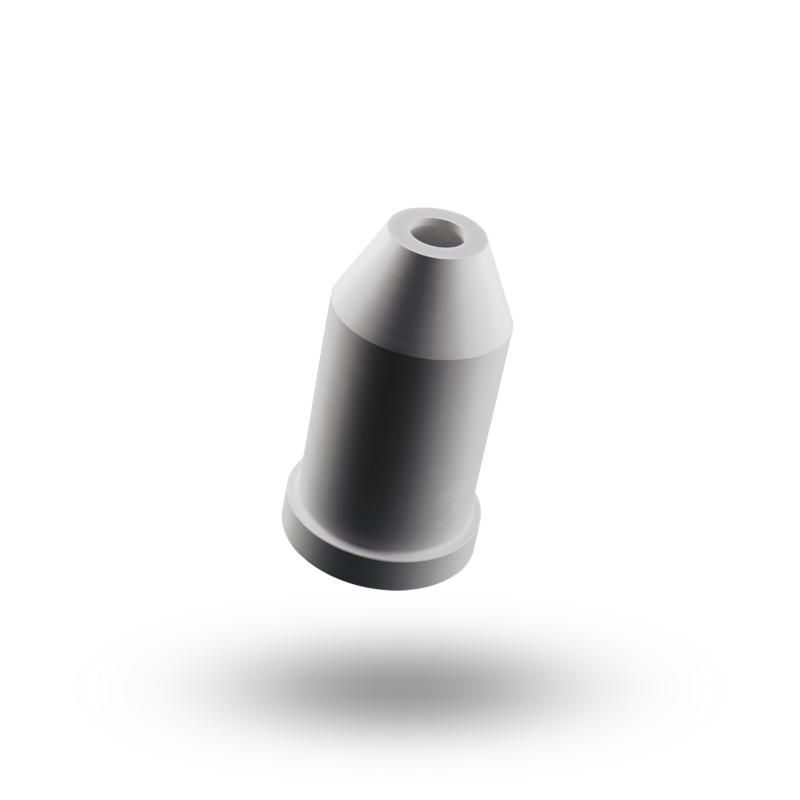

Sprue nozzles in foundry technology

Our sprue nozzles made of high-performance ceramics - StarCeram AT - are ideal for use in low-pressure die casting in the transition to the mold.

The sprue nozzles must ensure an even and controlled flow of material in order to produce high-quality casting parts with low tolerances and optimum surface quality. Technical ceramics from Kyocera guarantee high wear resistance, temperature resistance and dimensional stability even at high temperatures.

Very low wettability

Our sprue nozzles made of high-performance ceramics have very low wettability with molten aluminium and other non-ferrous metals. This maximises service life and reduces maintenance and downtimes.

Excellent corrosion resistance

Excellent corrosion resistance to non-ferrous metal melts is particularly important in order to prevent contamination of the melt and thus ensure the high quality of the cast part.

Very good thermal insulation

Thanks to their excellent thermal insulation, our sprue nozzles are an optimal solution for applications where very precise temperature control and low temperature loss are required.