the right solution for every requirement

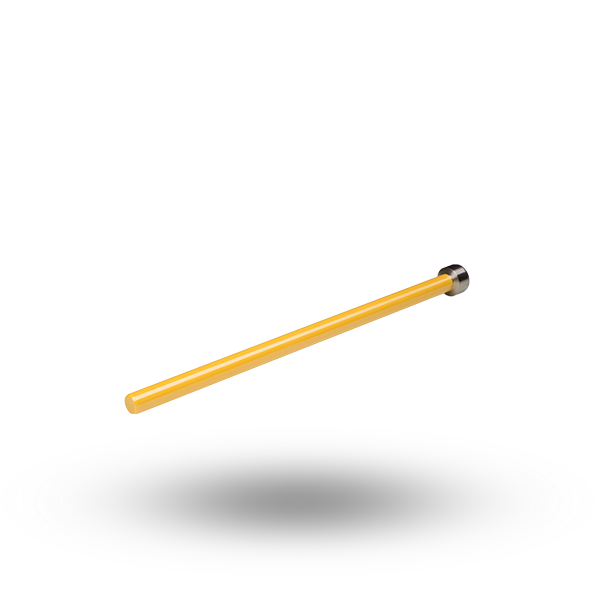

Carbide Alternative: Ceramic pistons from Kyocera

Whether used as homogenisers for the food and cosmetics industries or as plungers for conveying liquid media at high pressure - our high-performance plungers made of high-strength ceramics impress with their special qualities and can be used as alternatives to carbide.

Our oxide ceramic materials FZT, FZM or F99.7 are chemically inert and therefore also suitable for use in contact with foodstuffs. The ceramic pistons are FDA-approved and USP Class VI certified.

Benefit from numerous advantages of our ceramic high-performance pistons in a wide range of applications, such as

- high wear resistance

- optimum sliding properties (Ra < 0.05 μm)

- pressure resistance up to 10,000 bar

- long service life of more than 4,000 h at 3,000 bar

- lower weight compared to carbide pistons

- low frictional heat generation

… and use them without hesitation even in highly regulated industries such as the food & pharmaceutical and chemical industries!

The pistons and ceramic plungers can also be easily combined with metals with a sterile joint guarantee. At the same time, the high surface quality of our materials always ensures minimal adhesion of flow products.

Applications of ceramic pistons

In addition to their use in homogenization, our pistons / plungers are also used in water cutting plants as well as desalination plants. Ceramic pistons also perform excellently in pressurised water systems as well as in circuit conveying for filtration, cooling, and flushing.

You are interested in our products or have a specific project enquiry?

Ceramic pistons for the highest quality demands

Ceramic pistons for homogenisers

In homogenisers, the components of a mixture are broken down into tiny particles by forcing the mixture through a small opening under high pressure of 2,000 bar. This process is used in the production of food emulsions (such as milk) and cosmetics, where an optimal mixture of ingredients is required. All components for homogenisation must withstand high pressure and metered product shocks. Elements such as pistons, valve seats and impact rings are subjected to high friction by the medium to be machined. Kyocera supplies high-strength ceramic pistons that are ideally suited for the demanding conditions in a homogeniser.

Ceramic plungers for high-pressure applications

Plunger pistons made of the ceramic materials FZM, FZT and F99.7 are used for pumping liquid to highly viscous media, even if they contain abrasive components. Our ceramic high-performance pistons are ideal for use in high-pressure applications such as submersible piston pumps.

Compared to plungers made of other materials, such as steel, ceramic plungers usually have much greater durability.

High-pressure pistons

Ceramic pistons are used to convey media ranging from liquid to high-viscosity substances. They are also exceptionally well-suited for extreme-pressure applications.

Ceramic pistons

Pistons made of high-performance ceramics can be used to safely control the barrier fluid and thus to reliably separate the food from the hydraulic fluid, e.g., when homogenising milk.