The right solution for every requirement

High-precision mirrors for extreme operating conditions

Mirrors made of technical ceramics offer maximum precision, dimensional stability and exceptional durability - even under the most extreme operating conditions. Our innovative ceramic mirrors are used successfully in space travel, astronomy, semiconductor technology and laser technology. The materials used, cordierite and silicon carbide, provide optimum conditions for durable, temperature-stable and high-precision mirror systems that leave traditional materials such as glass and metal far behind.

You are interested in our products or have a specific project enquiry?

Advantages of ceramic mirrors at a glance

Minimal thermal expansion for maximum precision

One of the biggest advantages of cordierite mirrors is their extremely low thermal expansion - even at highly fluctuating temperatures. This guarantees maximum dimensional stability and prevents thermally induced deformations, which often occur with glass or metallic mirror substrates.

Outstanding stiffness-to-weight ratio

Thanks to state-of-the-art lightweight structures, ceramic mirrors can achieve weight reductions of up to 70 %* compared to conventional low-CTE glass without losing stability due to their excellent specific stiffness (Young's Modulus/Density).

*based on Kyocera's research

Chemical resistance and durability

Mirrors made of silicon carbide are extremely corrosion-resistant and can withstand even the most aggressive environments, such as those found in vacuum chambers, semiconductor processes or laser applications.

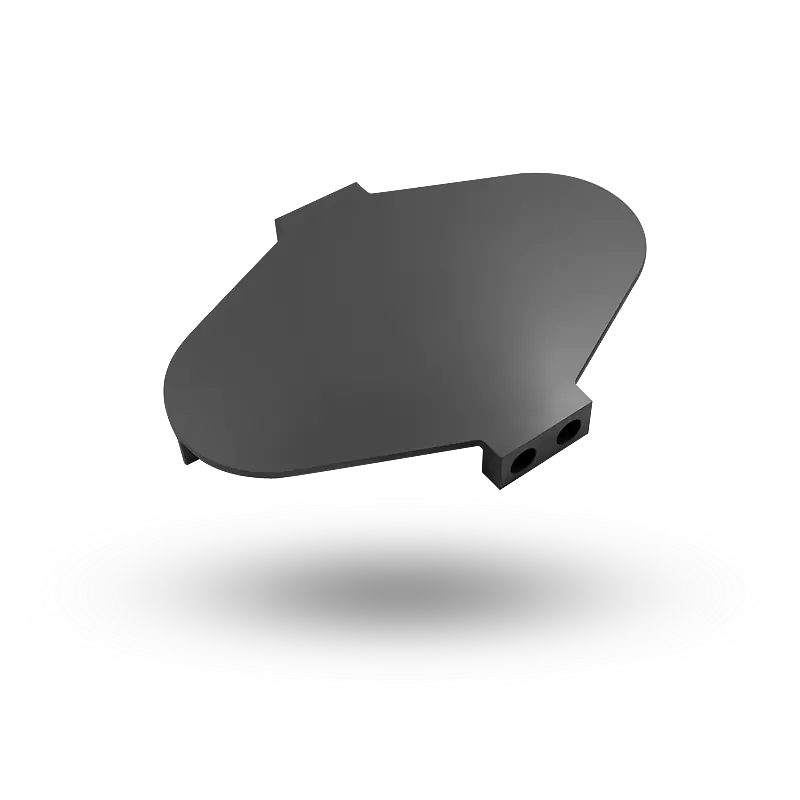

Design flexibility for highly complex structures

The manufacturing technology developed by Kyocera enables the realisation of complex and large-volume mirror structures - including integrated cooling channels and fusion bonding. This allows customised solutions to be developed for applications in aerospace, astronomy and high-end metrology.

Resistance in ultra-high vacuum (UHV)

The possibility of CVD-SiC coating prevents outgassing and enables extremely low contamination rates to be achieved, making the mirrors ideal for applications in ultra-high vacuum, such as in semiconductor production or space technology.

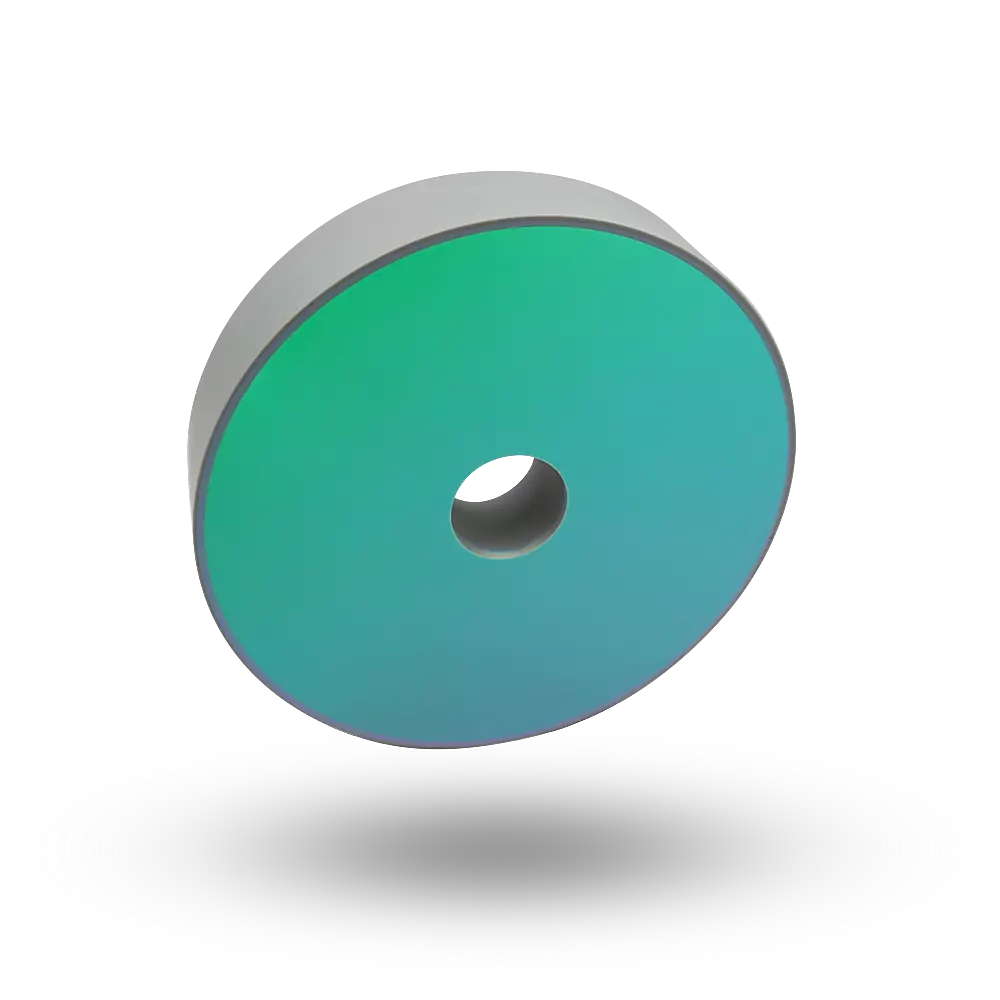

Mirrors made of silicon carbide (SSiC/SiSiC)

Material properties

- Outstanding temperature resistance:

Silicon carbide is stable up to 1,600 °C and is suitable for applications with extreme thermal conditions. - Very high rigidity with low weight:

Silicon carbide enables high-precision mirror structures and mechanically resilient large components with minimal deformation. - Excellent chemical resistance:

Silicon carbide resists aggressive media, like acids, alkaline solutions and solvents and is therefore ideal for applications in ultra-high vacuum (UHV), semiconductor processes and laser systems. - CVD SiC coating:

The optional coating reduces contamination from particles and outdiffusion of contaminants in applications >1000 °C to below 3 ppm - perfect for high-purity production environments. - Design flexibility:

Our production capabilities enable the manufacturing of complex, monolithic structures and the integration of water- or gas-cooled cavities.

Typical applications

- Mirror systems for laser technology:

The high temperature resistance and stability under thermal stress make silicon carbide the first choice in high-performance laser systems. - Mirrors in semiconductor technology:

Thanks to the CVD-SiC coating, silicon carbide mirrors are ideal for ultra-high vacuum applications, e.g. in wafer handling or etching processes. - Mirrors for space and satellite systems:

Silicon carbide offers high rigidity at low weight and is ideal for carrier mirrors and structural elements in satellites where high mechanical stability is required. - Mirror systems exposed to thermal stress:

Ideal for applications with high temperature changes, such as in optical sensors or laser applications in a vacuum.

Fine Cordierite Mirrors

Material properties

- Extremely low thermal expansion:

Fine Cordierite has a linear coefficient of thermal expansion of just 0.02 ppm/K. This means that the mirror geometry remains constant even with large temperature fluctuations - a decisive advantage in high-precision optical systems. - High specific rigidity:

Due to its low weight and high inherent rigidity, Fine Cordierite can be designed to be particularly light and dimensionally stable at the same time. This enables the construction of large-format mirrors with light-weight structures. - Weight reduction of up to 70 % compared to low-CTE glass:

Particularly advantageous for mobile and orbital systems where mass saving is crucial. - Excellent long-term precision:

Cordierite mirrors retain their optical quality even during long-term missions or at frequently changing operating temperatures.

Typical applications

- Satellite optics:

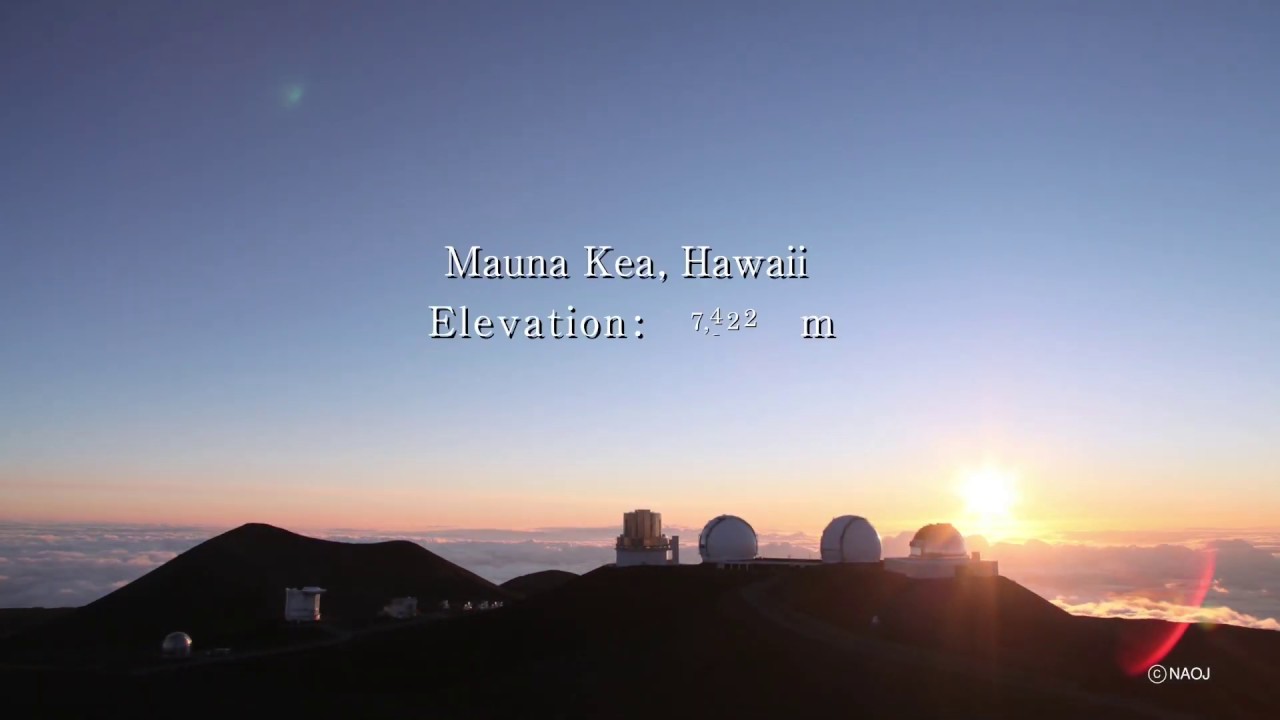

Satellite optics: Low weight and high stability make Fine Cordierite the perfect choice for mirror systems in satellites, where any reduction in mass reduces fuel consumption and increases system efficiency. - Telescope mirrors:

Cordierite is used for lens carriers in the Subaru Telescope in Hawaii, to ensure high optical stability despite temperature fluctuations. - Primary and secondary mirrors in astronomical systems:

Large-format cordierite mirrors are ideal for space telescopes where thermal stability is required over long periods of use. - Optical benches and mirror mounts:

Thanks to its high rigidity and dimensional accuracy, Fine Cordierite is optimal for stable platforms and optical alignment structures.