Ceramic as an essential material for oxygen measurement on the ISS

To material researchers, the Electromagnetic Levitator (EML) research lab is one of the most important facilities on the International Space Station (ISS). Demands placed on the materials used in it are therefore high and extremely relevant for the smooth functioning of the facility and the research findings gained from it. From 2025, KYOCERA Fineceramics Europe GmbH will be supplying tubes made of DEGUSSIT zirconium oxide for the extension of the EML on the ISS. The ceramic products help measure oxygen and are part of a new research facility that is constantly being expanded.

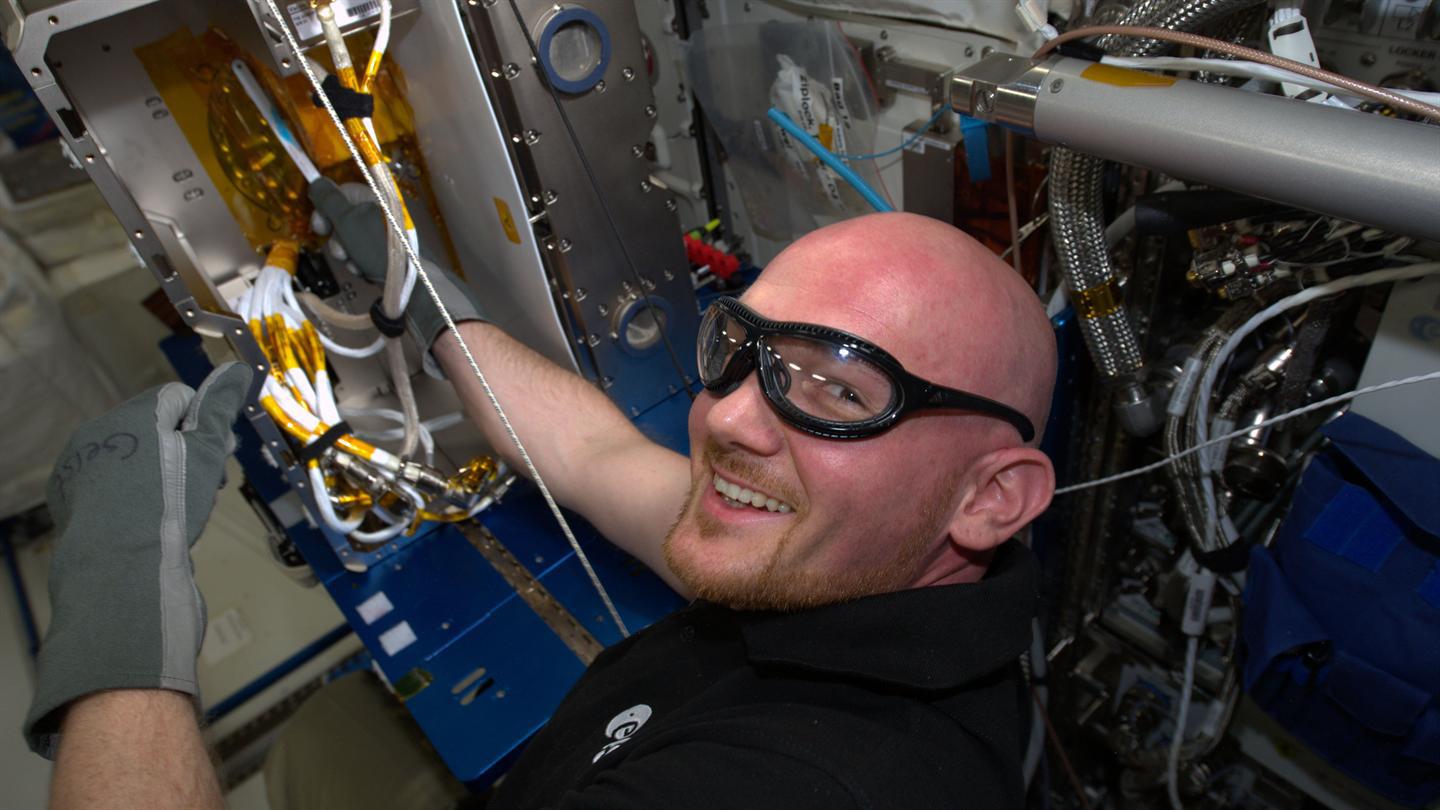

The Levitator is a 360 kg facility in the materials science laboratory in the Columbus module and was brought to the ISS in 2014 by the ATV-5 (automated transfer vehicle) "Georges Lemaître", an unmanned supply spacecraft. After it arrived, the system was installed and commissioned by Alexander Gerst who also supervised the sample processing. The EML is controlled and monitored by the DLR Microgravity User Support Centre (MUSC) in Cologne. Since its commissioning, the EML facility has achieved valuable results in the field of materials science research and will continue to be supported by the clients ESA and DLR in the future and expanded with new functionalities. In the context of the European Space Agency's (ESA)1 funding program, the EML will be expanded to include an oxygen measurement and control system (EML OCS - EML Oxygen Sensing and Control System) which is currently undergoing extensive testing and is expected to be transported to the ISS at the end of 2024. This will allow additional measurements under a specifically adjustable oxygen atmosphere.

1ESA Contract 21788/08/NL/BJ [EML (Electro-Magnetic Levitator) Phase B2/C/D Development] – Contract Change Notice 49 [EML OCS (Oxygen sensing and Control System) Phases C/D/E1 Development

Alexander Gerst at the melting furnace of the EML plant (Photo: NASA/ESA)

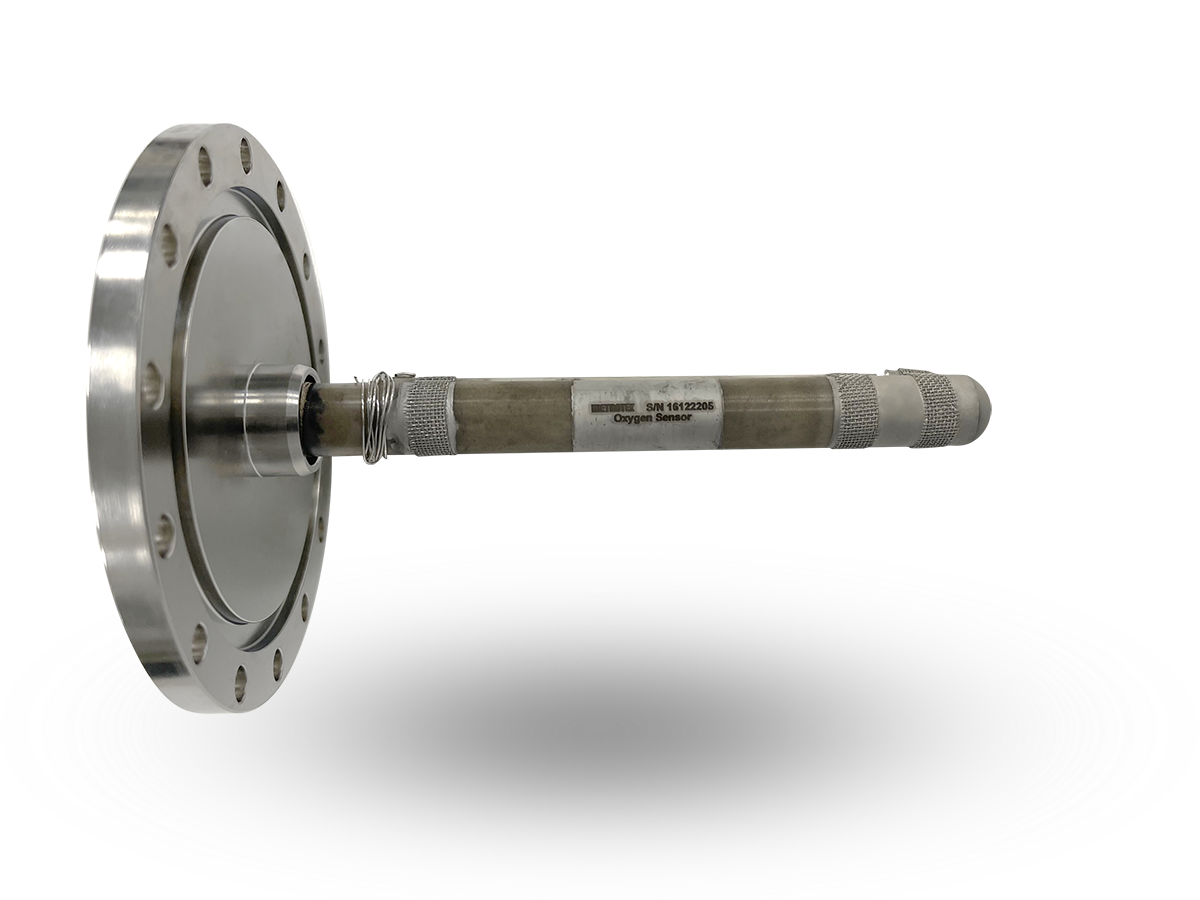

Kyocera supplies essential material for oxygen measurement

The expanded version of the system that will incorporate the possibility of oxygen control (OCS) will include two sensor assemblies including metallized and soldered ceramic tubes made of DEGUSSIT FZY supplied by KYOCERA Fineceramics Europe GmbH. DEGUSSIT FZY is a special material that, due to its ion conductivity, enables precise oxygen measurement at high temperatures. This ionic conductivity can only be achieved through specific adjustment of the composition and the ceramic microstructure. Extensive tests of the assemblies were carried out in advance to ensure their usability and reliability under the extreme conditions of rocket launches and weightlessness.

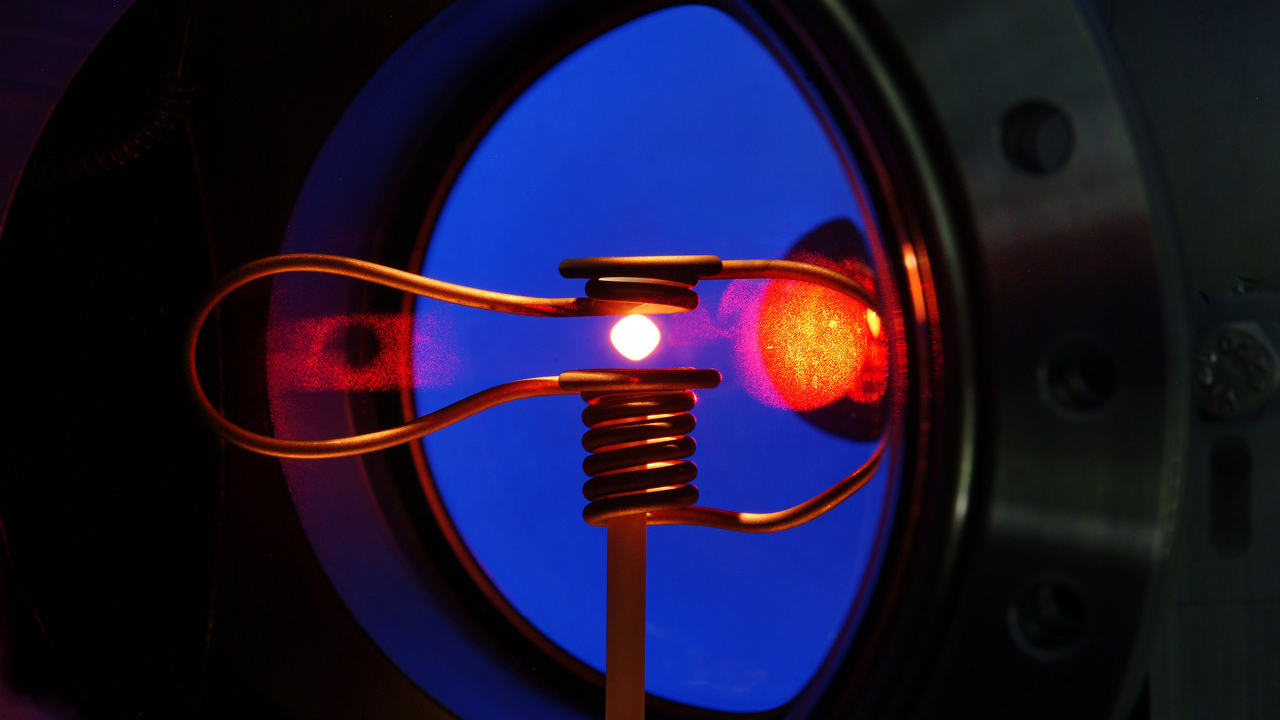

The Electromagnetic Levitator (EML) in use

The EML uses electromagnetic fields to position suspended floating metal and semiconductor samples. It also allows the materials to be melted, and various material data to be recorded at different temperatures. The process takes place in a vacuum or inert gas atmosphere. Without contact to a crucible wall, which would lead to measurement interference due to the contact between sample and crucible, or the influence of gravity, which may cause convection and segregation processes, material data can be determined more precisely and the behavior of metal alloys and semiconductors in weightlessness can be studied. Samples can be melted at temperatures between 400 and 2000 °C. The material data are recorded using a high-speed camera and a pyrometer (radiation thermometer).

The EML was developed by Airbus Defence and Space and commissioned by the European Space Agency (ESA) and the space management department2 of the German Aerospace Center (DLR). The EML is controlled and monitored by the DLR Microgravity User Support Center (MUSC) in Cologne. Since its commissioning, the EML facility has delivered valuable results in the field of materials science research. It will continue to receive support through commissions from ESA and DLR, and expand by incorporating new functionalities.

The EML system was developed by Airbus Defence and Space on behalf of the European Space Agency (ESA) and the Space Agency2 of the German Aerospace Center (DLR)

2 DLR Space Management Contracts 50WP0505, 50WP0606, 50WP0808

The opinions expressed here are not to be understood as official opinions of the European Space Agency (ESA) or the German Aerospace Center (DLR).