Kyocera will be exhibiting its high-performance functional and structural ceramics for aerospace applications at Space Tech Expo Europe

Kyoto/London − Non-conductive functional ceramics and wear-resistant structural ceramics are vital materials for the aerospace industry. Parts and system components made of these materials behave reliably, even under the most extreme conditions. These include environments with temperatures between absolute zero and several hundred degrees Celsius. The materials are also highly resistant to radiation and can provide protection for sensitive electronics.

KYOCERA Fineceramics Europe GmbH is specialised in manufacturing ceramic parts for the aerospace industry in all required quantities. This involves energy-efficient sintering techniques to produce ceramics with high strength and temperature resistance, additive manufacturing techniques to produce components with stringent structural requirements, and monolithic integration techniques that combine electronic components with radiation-proof ceramic casings in a particularly compact manner.

Precision and sustainability with cordierite and silicon infiltrated silicon carbide (SiSIC)

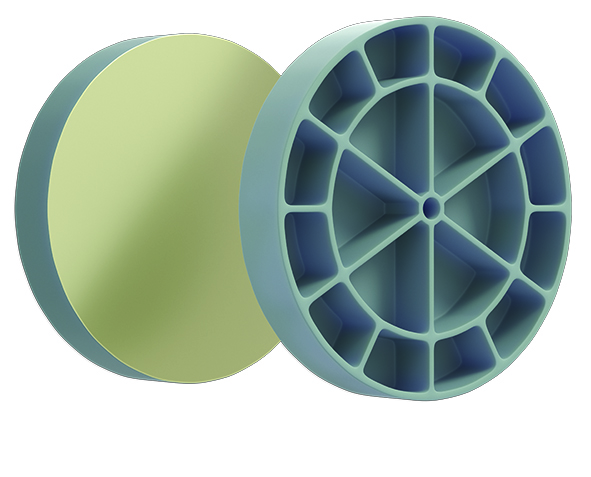

At Space Tech Expo Europe, Kyocera will present its latest components made of cordierite, a functional ceramic with minimal thermal expansion coefficients. This enables weight reductions of up to 70 percent compared to other materials with similar mechanical properties and makes cordierite suitable for both high-temperature insulation and high-precision functional parts, such as fine-adjusting mirrors in laser-based communication systems.

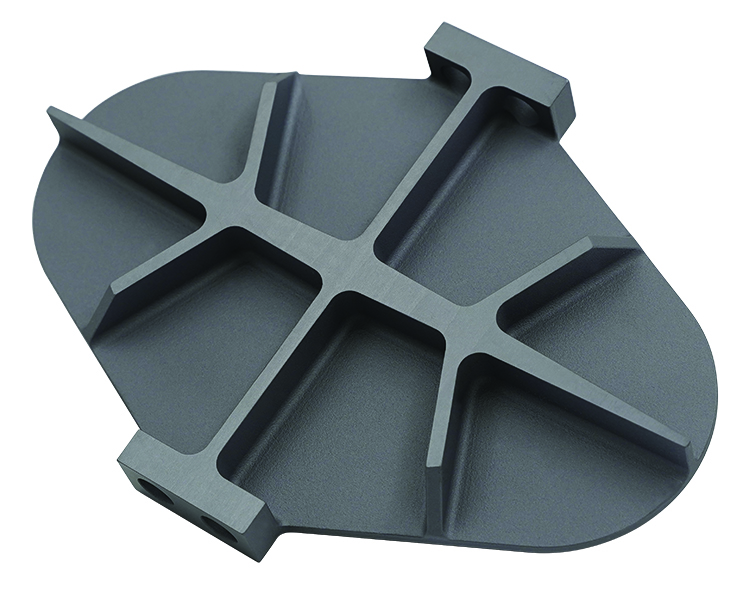

The high-strength ceramic silicon infiltrated silicon carbide (SiSIC) is also highly resistant to mechanical and thermal stresses, and requires significantly less cooling than metallic components. Proprietary processing techniques also allow the production of monolithic components with hollow structures that can be used for internal cooling. Silicon carbide and silicon nitride also offer outstanding resistance to rapidly changing temperatures. This makes them perfect for use in engine construction. As such, ceramic materials are making an important contribution to achieving the European Commission's Flightpath 2050 targets, which include a reduction in fuel consumption.

Innovative materials for the next round in "New Space"

"There is an extreme boom going on around space innovations at the moment," says Dr Carsten Rußner, President of KYOCERA Fineceramics Europe GmbH. "The focus is particularly on the economic systems of the future, such as the basics of satellite and communication technology for autonomous driving. Kyocera is also committed to developing advanced materials and technologies in these areas in order to continue achieving milestones that both reflect progress and enrich the lives of all. For this, it is essential to have industry-experienced development partners with the right materials and manufacturing techniques, as well as regional supply chains."

Kyocera's portfolio includes classic oxide ceramics that range from aluminium oxide to zirconium oxide and non-oxide ceramics – such as nitrides and carbides of silicon and titanium – as well as ceramic-metal composites for ultravacuum applications.

Details of the Kyocera stand

| Trade fair | Space Tech Expo Europe |

|---|---|

| Date | 14 to 16 November 2023 |

| Venue | Bremen, Germany |

| Kyocera stand | Messe Bremen Hall 6, booth #V31 |