Technical ceramics for the security and defence industry

Modern protection and security systems require materials that function reliably under extreme conditions. The high-performance ceramics from KYOCERA Fineceramics Europe GmbH combine high hardness and wear resistance with low weight, electrical insulation and stable thermo-mechanical properties – ideal for durable components in (high-frequency) sensor technology, protective applications, drive and mechanical systems, as well as communication and electronics. Precise manufacturing and application-specific design result in components that increase performance, availability and safety. The portfolio ranges from alumina (Al₂O₃) to silicon carbide (SiC / SiSiC) and silicon nitride (Si₃N₄) to zirconia (ZrO₂) and sapphire – tailored to the respective combination of requirements.

Your reliable partner

As a member of the Federal Association of the German Security and Defence Industry (BDSV), we underline our commitment to the highest industry standards, partnership and compliance. With our global network, a broad portfolio of high-performance ceramics, consistent quality assurance and co-development with our customers, we are the reliable partner for security-related applications.

You are interested in our products or have a specific project enquiry?

Advantages of technical ceramics from Kyocera

- Reliability under extreme conditions: Resistant to high temperatures, abrasion, corrosion and electromagnetic influences.

- Weight and performance advantages: High hardness with low weight – ideal for protection systems and mobile platforms.

- Electrical insulation & heat conduction: Insulating and heat-conducting components for safe electronics and stable signal transmission.

- EU manufacturing & compliance: All products and technologies shown are manufactured exclusively in the EU and provided in accordance with applicable export and foreign trade regulations (including AWG, AWV, EU Dual-Use Regulation). Provision or export to countries or applications subject to export restrictions is excluded.

Fields of application in sensitive operational environments

Sensors & Optics

Precise housings, high-frequency (HF) compatible components, transparent windows, insulators, traveling-wave tubes and components for pressure sensors.

Protective applications

Ceramic plates for protection systems with high resistance and low weight.

Drive & Mechanics

Lightweight, wear- and temperature-resistant components for systems under continuous load – e.g. heavily loaded shafts, bearings or forming tools.

Communication & Electronics

Electrically insulating and thermally conductive components for reliable signal transmission; including mirrors/substrates.

Ceramic materials in high-reliability applications

Alumina

Properties & advantages

- Electrical insulation: very high dielectric strength → safe separation in high-voltage/high-frequency assemblies.

- Temperature resistance: dimensional and property stability at high temperatures up to 1800 °C.

- Low porosity / fine structure: precise sealing surfaces, good surface quality after grinding/lapping.

- High wear/corrosion resistance

- Low weight and extremely high specific stiffness.

- Process advantages: proven metallisation (e.g. Mo-Mn, W) and brazeability → hermetic packages.

- Comprehensive expertise in the manufacture of ceramic-metal composite components.

Typical security applications

- Insulators & bushings in modules for high-frequency sensor technology

- Housings/carriers

- Guide, sealing and wear rings in mechanical assemblies

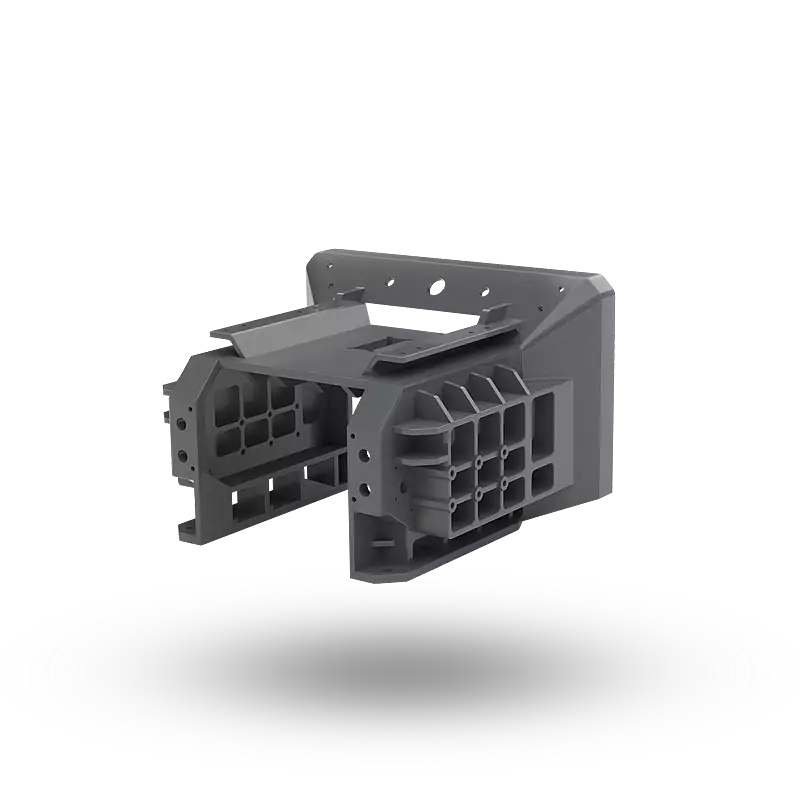

Silicon carbide (SiSiC / SiC)

Properties & advantages

- Very high hardness with low density: weight savings in protective systems, high penetration resistance.

- High thermal conductivity & rigidity: effective heat management, dimensionally stable under load.

- Corrosion and oxidation resistance: suitable for demanding environments.

- Low thermal expansion: low tendency to warp during temperature changes.

- Low weight and extremely high specific stiffness.

- Highly complex structures are possible even for large-volume components thanks to 3D printing and precision machining of SiSiC.

Typical security applications

- High-temperature structural parts and mirror/substrate structures in precision systems

- Abrasion/erosion parts (nozzles, liners, protective plates)

- High-temperature exhaust pipes

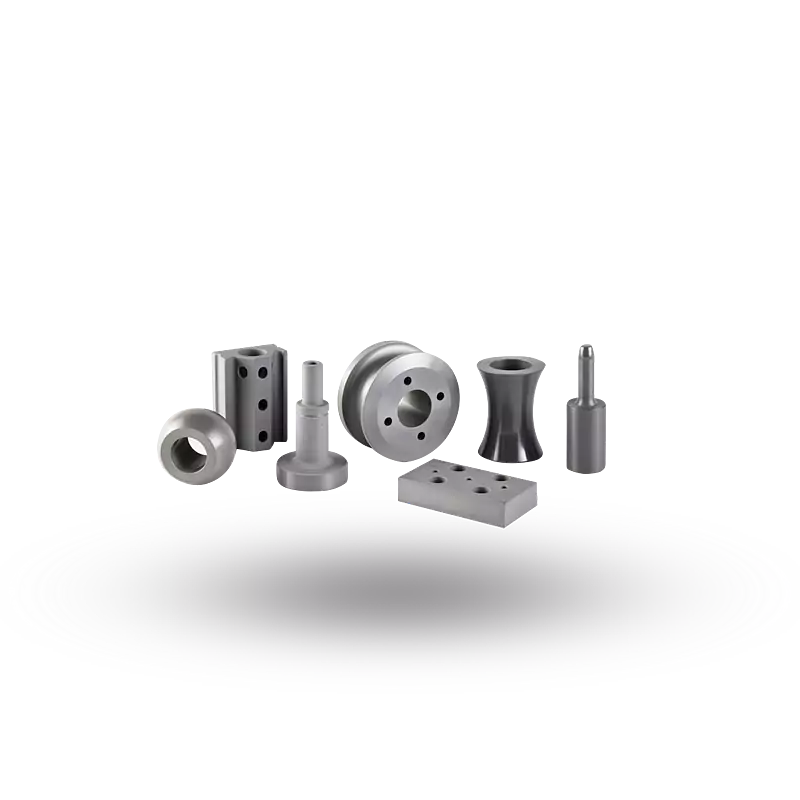

Silicon nitride (Si₃N₄)

Properties & advantages

- High strength and toughness

- Good thermal shock resistance: suitable for cyclic temperature profiles.

- Low density, good wear resistance: lightweight construction for rotating/sliding parts.

- Low weight and extremely high specific stiffness.

- Dimensional stability at elevated temperatures.

- Laser processing possible

Typical security applications

- Bearing bodies/rollers, shaft guides, high-speed mechanics

- Drive/structural components with combined mechanical and thermal loads

- Nozzles, valve/seat components in demanding media

- Heat management for electronics

- Radomes

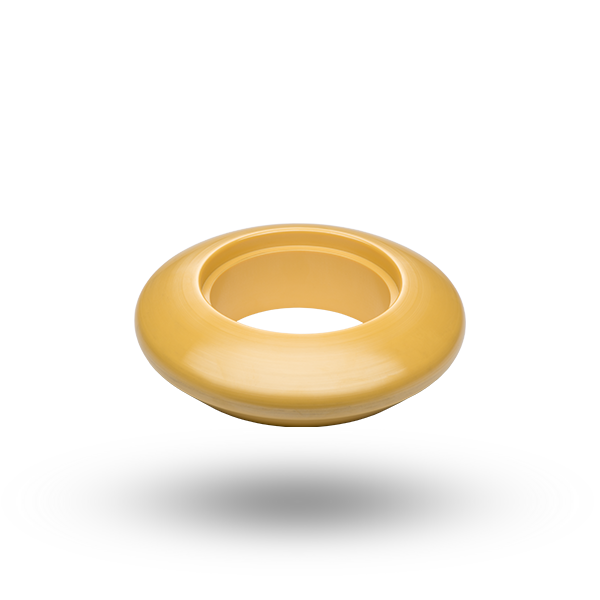

Zirconia (ZrO₂)

Properties & advantages

- Very high toughness

- Low thermal conductivity: suitable for thermal insulation.

- Precise fits possible (good grindability/polishability), smooth running in couplings.

- Electrical insulation, corrosion resistant.

Typical security applications

- Coupling/connecting elements, damper/support rings

- Valve/seat components, precision guide components

- Insulating spacers in assemblies with micro shock loads

- Tools for metal forming

Sapphire (single crystal alumina)

Properties & advantages

- Optical transparency across broad spectral ranges; scratch/erosion resistant.

- High hardness/rigidity: resistant to particle impact and abrasion.

- Smooth, polishable surfaces: low scattering, optionally with AR coatings.

- Thermally stable, chemically inert.

- Low weight and extremely high specific stiffness

Typical security applications

- Sensor/camera windows, viewing and protective windows

- Transparent protection in harsh environments (sand/salt/dust)

- Domes/covers for optical systems

FAQ

Areas of application include (high-frequency) sensor technology, body and vehicle protection, drive systems, electronics and communication components.

Technical ceramics combine high hardness and rigidity with low weight and resistance to wear, corrosion and high temperatures.

Yes. Kyocera develops tailor-made solutions in co-development – from material selection to design and prototyping to series production.

The portfolio includes alumina (Al₂O₃), silicon carbide (SiC / SiSiC), silicon nitride ( , Si₃N₄), zirconia (ZrO₂) and sapphire. Each material meets specific requirements ranging from hardness and wear resistance to transparency or high fracture toughness.

Yes – e.g. precision housings, transparent windows and RF-compatible components with defined dielectricity.

Silicon carbide (SiC) is often used for protection systems; it combines low weight with high hardness.

Kyocera's ceramic components are manufactured at three production sites in Germany: Mannheim, Selb and Erfurt.

Yes, ceramic products can be printed from silicon-infiltrated silicon carbide (SiSiC) using the binder jetting process. Other materials for 3D printing are available on request.

Our production facilities are designed for both prototype manufacturing and highly automated series production.