Technical Ceramics for the Oil & Gas Industry

In the oil and gas industry, materials are continuously exposed to extreme conditions: high pressures, temperatures reaching up to 1,800 °C, abrasive particles, corrosive fluids and constantly changing media compositions. Under these circumstances, metallic and polymer-based materials quickly reach their limits. Technical ceramics offer decisive advantages—they remain dimensionally stable, wear-resistant and chemically robust, even under continuous load.

The technical ceramics manufactured by KYOCERA Fineceramics Europe GmbH are used in numerous oil and gas applications—from pump and valve components to seals and bearings, as well as sensors, measurement systems and erosion protection solutions. Due to their high hardness, temperature resistance and corrosion resistance, they ensure maximum plant availability and reduce maintenance and downtime to a minimum.

Moreover, technical ceramics enable precise and reliable process control in highly demanding environments—such as drilling operations, compressor stations, refineries or offshore installations. Thanks to their excellent electrical and thermal insulation properties, they are suitable not only for mechanical components but also for electronic and sensor systems.

With decades of experience in developing and processing high-performance ceramics, Kyocera provides customized solutions for the energy and process industries. The result: extended service life, higher efficiency and sustainable operation—even under the harshest conditions of oil and gas production.

You are interested in our products or have a specific project enquiry?

Application Fields in the Oil & Gas Industry

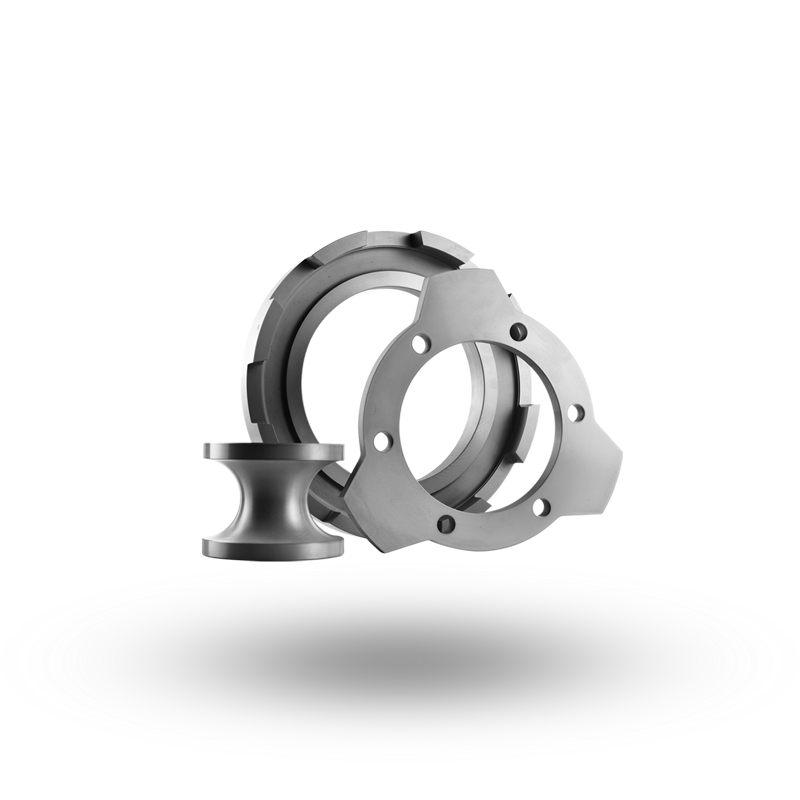

Pump and Valve Technology

Ceramic components are used wherever abrasive media and chemically aggressive fluids would destroy metallic parts.

Sealing and Bearings

In compressors, pumps and drilling drives, ceramic sealing rings, sliding discs and bearings ensure continuous operation—even in highly aggressive environments.

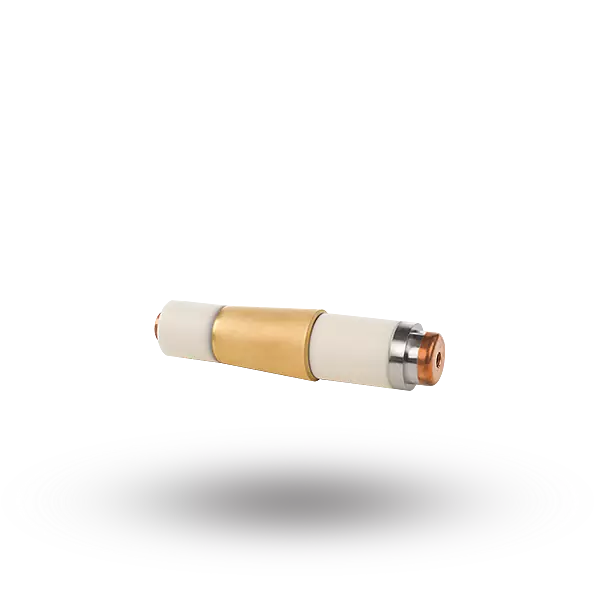

Sensor Technology and Measurement Systems

Ceramic components ensure precise measurement results, even under extreme conditions.

High-Temperature and Insulation Applications

In drill heads, tool inserts or downhole components, ceramics provide effective insulation against heat and aggressive media.

Ceramic Materials Used in the Oil & Gas Industry

Silicon Carbide (SiC / SSiC)

Advantages:

- Very high hardness: excellent protection against abrasion and erosion

- Resistant to corrosive media, slurries and aggressive fluids

- Temperature stability under extreme process conditions

- High thermal conductivity: efficient dissipation of process-related heat

- Excellent dimensional stability under pressure and temperature fluctuations

Typical applications:

- Pump and conveying components such as plungers, pump liners, valves, sealing parts, pipes or cylinders

- Mechanical seals and bearings

- Nozzles, flow components, erosion protection parts

Silicon-infiltrated Silicon Carbide (SiSiC)

Advantages:

- High strength and very high rigidity

- Outstanding resistance to abrasion, erosion and chemically aggressive media

- Excellent high-temperature mechanical performance

- Excellent thermal shock resistance

Typical applications:

- Pump and conveying components such as plungers, pump liners, valves, sealing parts, pipes or cylinders

- Flow-guiding and mixing components

- Linings, bushings, nozzles

Silicon Nitride (Si₃N₄)

Advantages:

- High strength and toughness even at elevated temperatures

- Excellent thermal shock resistance: ideal under rapid load and temperature changes

- Low friction and wear resistance in dynamic applications

- Low thermal expansion: high dimensional stability

- Resistant to corrosive and erosive media

Typical applications:

- Wear-protection components for extremely abrasive media or heavy loads

- Protective and guide tubes for corrosive, abrasive or chemically aggressive media

Alumina (Al₂O₃)

Advantages:

- Excellent electrical insulation: essential for sensors, feedthroughs and measurement systems

- High wear and corrosion resistance against aggressive media

- High mechanical strength and stability at elevated temperatures

- Long service life and reliable performance in complex process environments

- Particularly suitable for metallization / ceramic-to-metal assemblies (hermetic sealing)

Typical applications:

- Sensor housings for pressure, level or humidity measurement

- Insulators

- Electrical feedthroughs

- Tubes

Zirconia (ZrO₂)

Advantages:

- High mechanical strength and exceptional fracture toughness

- High resistance to cavitation: essential for valve and control applications

- Excellent dimensional stability under dynamic loads

Typical applications:

- Sensor components

- Pump components such as containment shells for magnetic pumps, plungers, valves and sealing parts, pipes or cylinders

FAQ

Because technical ceramics exhibit extreme hardness and chemical resistance. They withstand abrasive particles, pressure and heat over long periods.

Ceramic linings minimize material removal and prevent erosion damage. Critical for conveying systems that handle sand or solid particles.

Due to low wear and high chemical stability, maintenance intervals become longer and downtime is significantly reduced.

Yes. Kyocera develops tailor-made solutions designed specifically for medium, temperature, pressure and geometry.

Depending on the material, up to approx. 1,800 °C without significant deformation or loss of function.