Joining oxide ceramics

Kyocera has more than 50 years of experience in the manufacture of ceramic-to-metal assemblies. The process experience, coupled with state-of-the-art equipment, enables the realisation of sophisticated customer-specific products.

Oxide ceramic materials such as alumina (Al₂O₃) and zirconia (ZrO₂) are characterised by outstanding properties such as high mechanical strength, temperature resistance and chemical resistance. In order to optimally utilise these advantages, we offer a variety of highly developed joining processes that are precisely tailored to technical requirements and extreme operating conditions.

Joining methods at a glance

1. Friction- and form-locked methods

These processes utilise mechanical principles to create a strong and resistant bond between ceramic and metal or other materials. They are particularly suitable for applications that require a simple and reliable assembly technique.

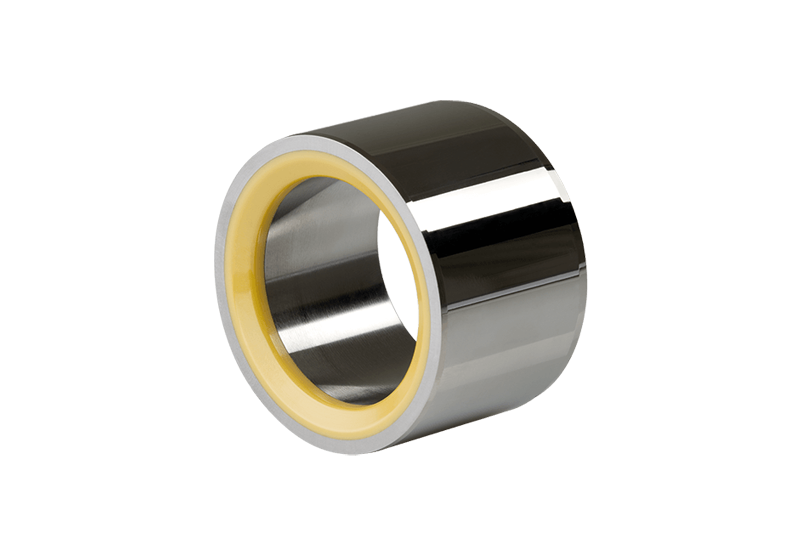

Shrink fitting

In the shrink-fit process, the metal part is heated and pressed onto the ceramic. After cooling, the metal contracts and forms a form-fit, solid connection. This process is favoured because it offers high reliability with low technical complexity and can be used under vacuum conditions.

Screws and rivets

Mechanical fastening methods such as screw connections or clamping devices are used. These methods offer a detachable connection and are suitable for applications with changing requirements or maintenance needs.

measurement - sintered cermet

2. Firmly bonded methods

Material bonding processes lead to molecular bonding of the materials and guarantee highly resilient and durable bonds with excellent thermal and chemical resistance.

Bonding with organic adhesives

This method uses duroplastic adhesives that achieve high strengths of up to 50 MPa at temperatures of up to 150 °C. These bonds are particularly suitable when a flexible and vibration-damping bond is required.

Glass soldering

Glass brazing alloys with expansion coefficients matched to the ceramic ensure vacuum-tight joints with high mechanical strength (up to 100 MPa). Brazing temperatures of up to 1400 °C enable sealed components for high-temperature applications.

Brazing with metallic brazer

The technology used is usually based on Mo/Mn metallisation of the ceramic base body at the joints. This is applied mechanically and fired at high temperature in a reducing atmosphere. Diffusion creates a material bond between the ceramic and the metallisation. In addition, a Ni layer is applied using various processes, such as galvanisation, to ensure the wettability of the joint. This metallised ceramic can then be soldered to metallic or other ceramic components. As a rule, high-melting brazing alloys are used here, which are joined in different furnace atmospheres such as inert gas or vacuum conditions.

Active brazing

In this brazing technique, high-melting, metallic brazing alloys are used, a certain percentage of which consist of reactive metals such as titanium, zirconium or hafnium. These solders enable a metallisation-free solder joint suitable for high vacuum. Strength values of over 120 MPa are possible.

Diffusion bonding

This process makes it possible to bond similar ceramic materials under high pressure and temperature. The result is a stress-free and high-strength joint with a homogeneous microstructure.

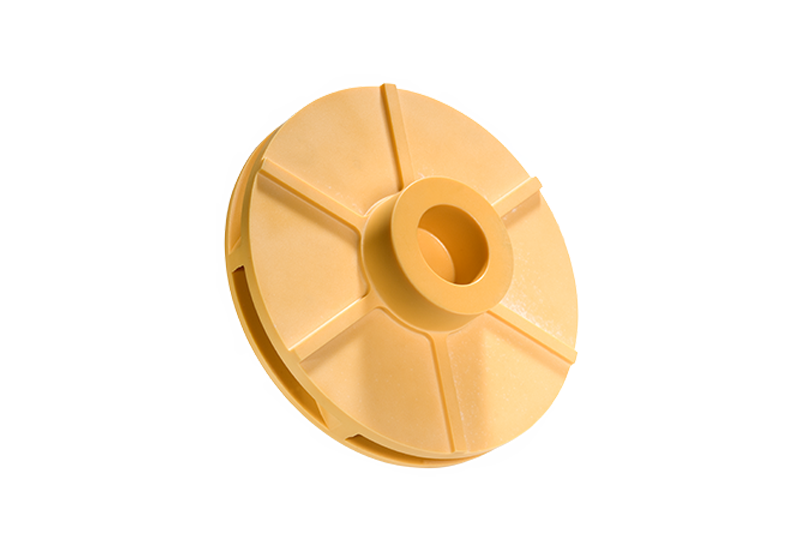

Co-firing

Co-firing involves sintering platinum electrodes or platinum cermets electrodes together with ceramic components in order to achieve an optimum bond and a high level of tightness. This technique is used, for example, for the production of measuring cells in sensor technology.

Product examples

Learn how your application can benefit from laser machining!

Design aspects for reliable joints

In order to minimise stresses and material fatigue, the thermal expansion between ceramic and metal must be carefully adapted in the design. By using ductile intermediate layers such as copper or special geometries, residual stresses can be reduced and the service life of the components extended.

Application examples

Our joining processes are used successfully in a wide range of industries:

- Electrical engineering: high-pressure feedthroughs, insulating components, explosion barriers in offshore technology

- Measurement and control technology: sensors for pressure and temperature measurement

- Medical technology: components for diagnostic radiology

Vacuum technology: UHV-tight feedthroughs and insulators

Your partner for high-precision oxide ceramic joints

With our many years of experience and innovative technologies, we develop customised solutions for your specific challenges. Contact us and let our team of experts advise you!