the right solution for every requirement

Safe and sterile grinding and crushing

Technical ceramic components are essential for the operation of high-performance mills used in industrial wet and dry grinding and in laboratories. Kyocera's high-performance ceramic components fulfil a wide range of demanding requirements, including high temperatures, corrosion, wear and thermal shock.

High corrosion resistance

Thanks to their excellent corrosion resistance, our high-performance ceramic components are ideal for applications in corrosive environments. This property combined with extreme hardness and strength ensures a long service life and reliable performance.

High wear resistance

Our technical ceramic components are ideal for applications with high mechanical stress as they are exceptionally wear resistant. Cost savings can be realised through extended service life, reduced maintenance intervals and increased efficiency.

Thermal shock resistance

Mill components made of high-performance ceramics are characterised by their excellent thermal shock resistance. This makes them suitable for applications where extreme temperature fluctuations occur.

High temperature resistance

Our technical ceramic components retain their integrity even at extreme temperatures, making them ideal for high-temperature applications.

Contamination-free grinding

Contamination-free grinding can be achieved by using components made of silicon nitride, silicon carbide, alumina and zirconia.

You are interested in our products or have a specific project enquiry?

Mill linings

Mills are an important part of many processes in industry, including the grinding, milling and crushing of materials. To ensure high efficiency and a long service life, they must be able to withstand a variety of stresses, including abrasion, chemical attack and high temperatures.

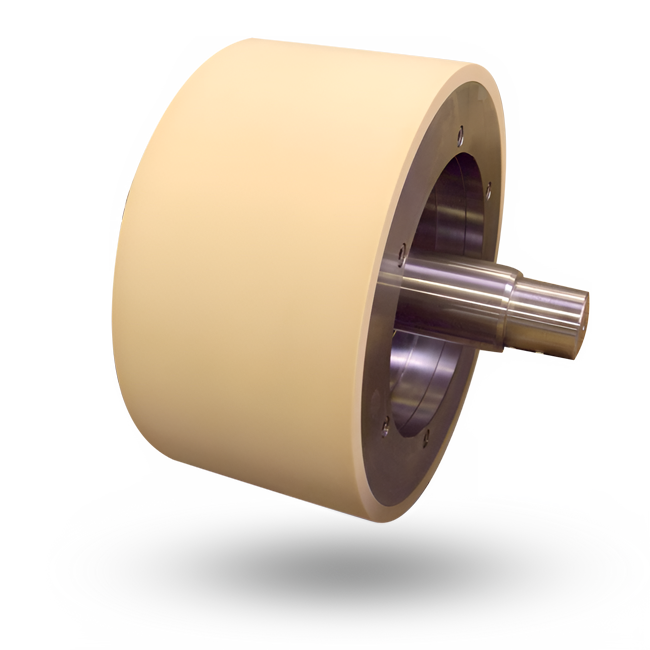

Separator wheels

Air classifier wheels are primarily used in the food, pharmaceutical and raw materials industries to classify regrind. To ensure high efficiency and a long service life, they must be able to withstand a variety of stresses, including high abrasion resistance, low weight and non-ferrous classification.

Roller body

Roller bodies made of technical ceramics are used in pairs to crush tough materials. The product is not contaminated, and the ceramic roller body made of alumina or zirconia easily withstands challenging applications.

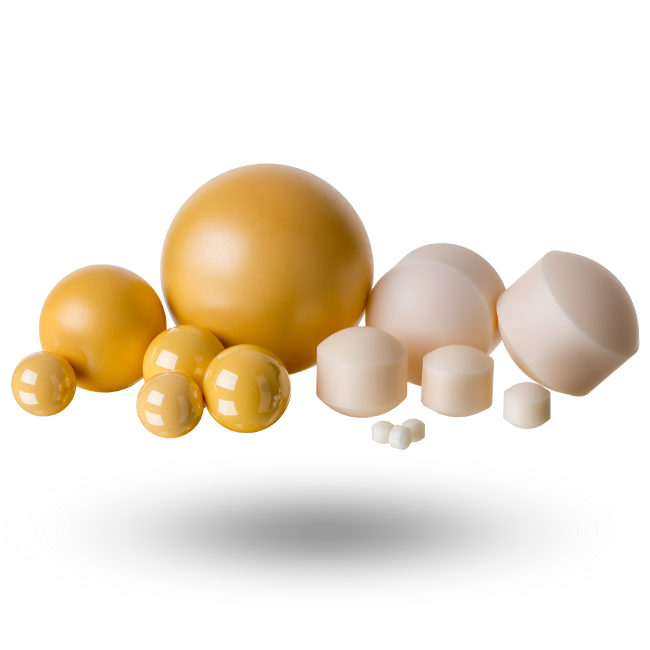

Grinding media

Grinding media made of high-performance ceramics are non-magnetic and are characterised by high wear resistance. The high chemical resistance and inertness allow them to be used even with extremely sensitive grinding material.

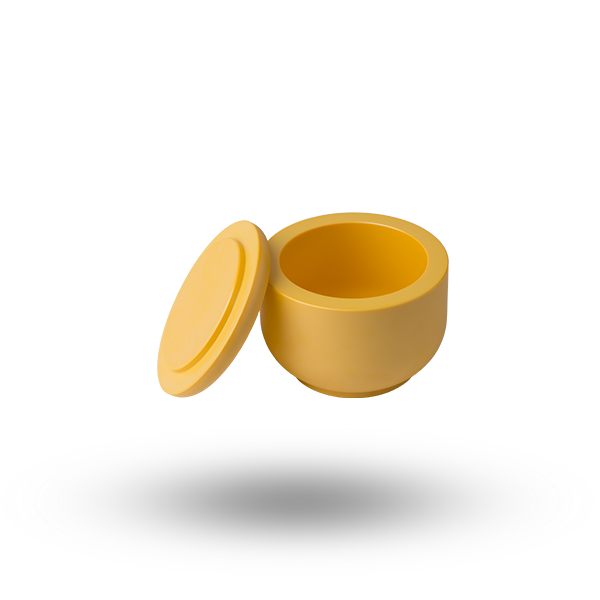

Grinding vessels

Kyocera's wear-resistant and FDA-certified materials enable the crushing of very hard and contamination-sensitive materials. We produce customised ceramic products for comminution and pulverisation, such as ceramic jars and ceramic grinding bowls. Their high chemical resistance and inertness allow them to be used even with susceptible grinding materials in pharmacological laboratories or in battery production. The use of our ceramic with a smooth surface prevents contamination of the processed samples, which can be caused by unwanted abrasion. Due to the unique ratio of flexural strength and modulus of elasticity, our ceramics have a high impact strength and chipping resistance. Our ceramic planetary ball mill jars are used in the paint production, medicine, food and cosmetics industries, among others.

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/produkte/Selb/mills_rotor_kyocera.png)