Sustainable minimisation of pollutants with high-performance fume scrubbers

Efficient exhaust air treatment for laboratories and industrial applications

Industrial and laboratory processes often release harmful air pollutants that are subject to strict legal regulations. Compliance with regulations such as the German Technical Instructions on Air Quality Control (TA Luft) or the German Federal Immission Control Act is essential to meet environmental requirements and minimise health risks. Our powerful fume scrubbers ensure efficient cleaning of chemically contaminated exhaust air directly at the source of emission and provide an economical solution for your company.

FRIDURIT fume scrubbers: high-performance technology for clean exhaust air

Our fume scrubbers have been specially developed for the removal of aggressive and toxic gases and offer numerous advantages:

- Decentralised cleaning:

absorption of pollutants directly at the source, e.g. in laboratory fume hoods - Individual configuration:

built-in types for existing systems or free-standing units for flexible use - Highly effective air washing:

effective binding of perchloric acid, hydrofluoric acid, sulfuric acid, hydrochloric acid and nitric acid - Environmentally friendly and efficient:

low water and energy consumption with maximum effect - Certified safety:

meets all relevant standards and laws (e.g. DIN EN 14175-7, DGUV 213-850)

Why choose Kyocera exhaust air purification?

For over 30 years, innovative fume scrubbers have been developed under the brand name FRIDURIT, manufactured according to German quality standards and covered by a 24-month warranty. Our proven cleaning technologies, such as the unique spray wheel system, ensure maximum efficiency at minimum operating costs.

Differences between washing with a spray wheel system and a washing column

Both designs can separate the contamination in the gas flow (air) from the gas flow with the help of a scrubbing liquid; this process is referred to as ‘scrubbing’. The principle behind it is absorption, i.e. the binding of the contamination to the scrubbing liquid.

Exhaust air scrubber with spray wheel system

In the case of exhaust air scrubbing with a spray wheel system, the contaminated gas stream is fed into the absorption chamber of the exhaust air scrubber.

The spray wheel draws in the uncharged scrubbing liquid and atomises it. The atomisation of the scrubbing liquid causes the scrubbing liquid droplets to become smaller, resulting in a larger surface area of the individual droplets. This surface is also the contact surface between the contaminant from the gas stream and the scrubbing liquid, where the absorption, i.e. the binding of the contaminant from the gas stream to the scrubbing liquid, takes place. This increased contact surface thus enables more effective absorption of the contaminant.

In addition, the permanent rotation of the spray wheel distributes the generated scrubbing liquid mist over a large area in the absorption chamber of the fume scrubber. The resulting increased mixing of the scrubbing liquid mist with the contaminated gas stream results in a more effective separation process. In addition, the even distribution of the fine scrubbing liquid droplets in the absorption chamber reduces the consumption of scrubbing liquid, which has a cost-effective and resource-saving effect.

Since the rising gas flow can cause the entrainment of loaded scrubbing liquid droplets, droplet separators are located in the exhaust air scrubber. The individual droplets collect on these, agglomerate and drip back into the absorption chamber.

The now cleaned exhaust air is then discharged from the exhaust air scrubber and the scrubbing liquid, which is laden with contaminants, remains in the scrubber.

The contact time between the gas stream and the scrubbing liquid is usually short, which is why faster scrubbing is possible than with a column.

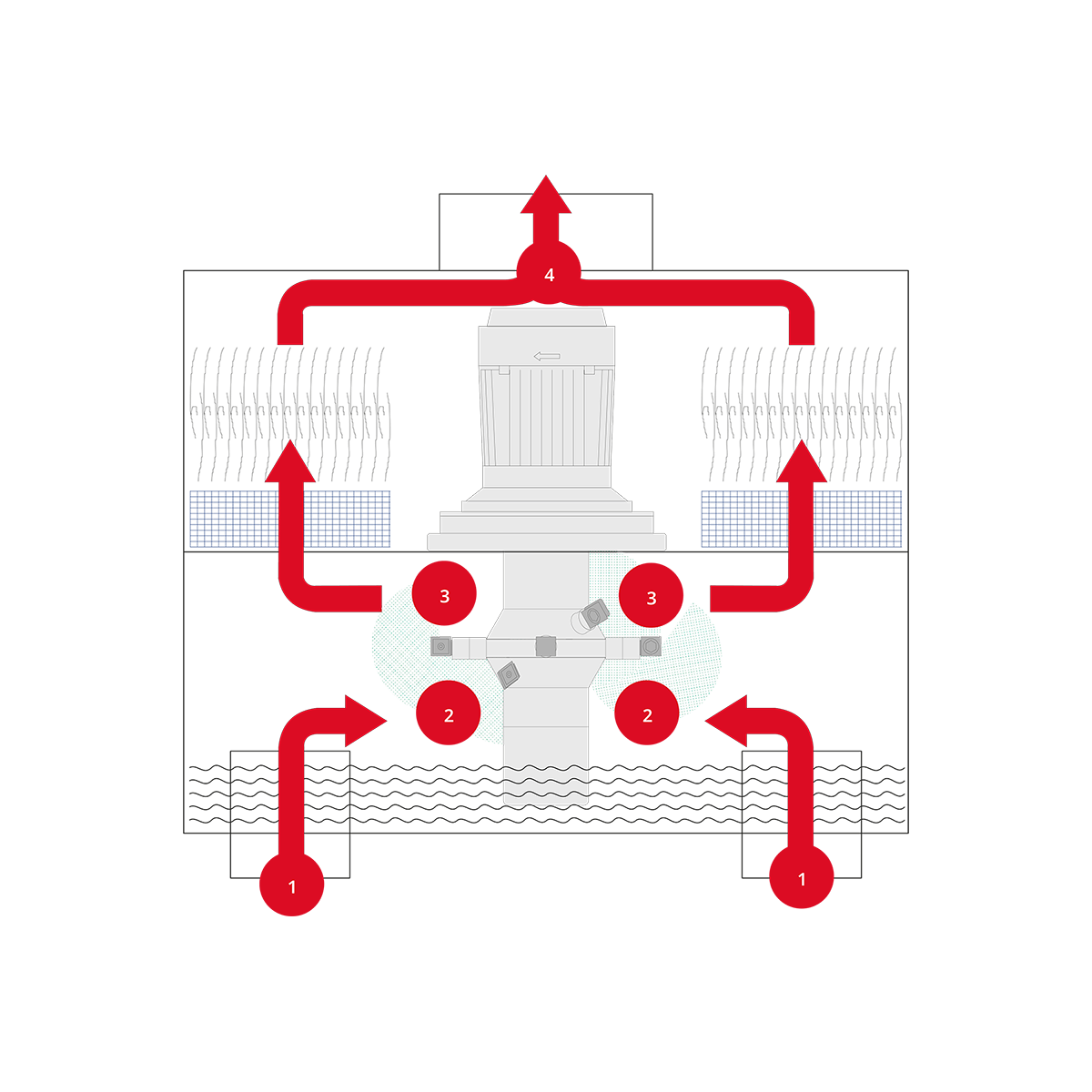

How the spray wheel scrubber works

- The contaminated exhaust air is drawn in through the noxious gas nozzles by the shortest route into the absorption chamber.

- The pollutants are intensively washed out in the scrubbing liquid mist generated by the conveyor and spray wheel.

- The absorption is optimised and the residual liquid is separated by agglomerators and mist eliminators.

- The cleaned exhaust air is fed through the clean air nozzle into the downstream ductwork.

Washing with a column

A column can also be used to separate a pollutant from its feed medium. In process engineering, they are not only used for absorption tasks, but also, for example, for gas cooling/quenching, heat recovery, adsorption, extraction, rectification/distillation or crystallisation.

As with the spray wheel-based fume scrubber, the contaminated gas flow is directed through the apparatus, where the contaminated gas comes into contact with the scrubbing liquid and is scrubbed. To achieve this separation, the columns are equipped with several internals arranged one behind the other, such as random or structured packings or trays.

The contaminated gas stream is scrubbed in the first segment and then passes to the second segment, where a further separation occurs. The same takes place in all the following segments. The repetitive separation in the column internals installed in series results in a higher separation efficiency.

Washing with a column is carried out over several equilibrium stages, which is why it takes longer than with an exhaust air scrubber with a spray wheel system. Columns are usually designed as vertical cylinders in which the length exceeds the diameter many times over, so a larger gas flow can be washed simultaneously with a column than with an exhaust air scrubber with a spray wheel system.

You are interested in our products or have a specific project enquiry?

Important criteria for selecting an exhaust air scrubber

- Lifespan & maintenance:

high-quality materials, made in Germany, and long service life of the devices - Energy & water efficiency:

optimised operating and consumption costs - Reduced pressure losses:

minimisation of energy consumption in ventilation technology - Quiet operation:

ideal for use in sensitive environments and consideration of occupational safety - Expandable equipment:

optionally available with pH measuring probes, flow sensors and differential pressure gauges - Europe-wide, certified service network

Typical applications:

- Laboratories & research centres

- Chemical industry & semiconductor production

- Battery production & mining

- Coating processes & laser marking

- Potentially explosive atmospheres (ATEX-certified versions)

Maximum separation efficiency – tested and certified

Our fume scrubbers offer impressive separation efficiency, which has been confirmed by TÜV for the C20 model, among others:

- Hydrofluoric acid (HF): up to 97%

- Sulfuric acid (H₂SO₄): up to 95%

- Hydrochloric and nitric acid (aqua regia): up to 70%

Product overview of standard models

Built-in fume scrubber

Fume scrubbers with an air output of up to 1400 m³/h for installation in fume cupboards.

Free-standing fume scrubber

Fume scrubbers with an air output of up to 1800 m³/h for free installation in case of low ceilings or when connecting several emission sources.

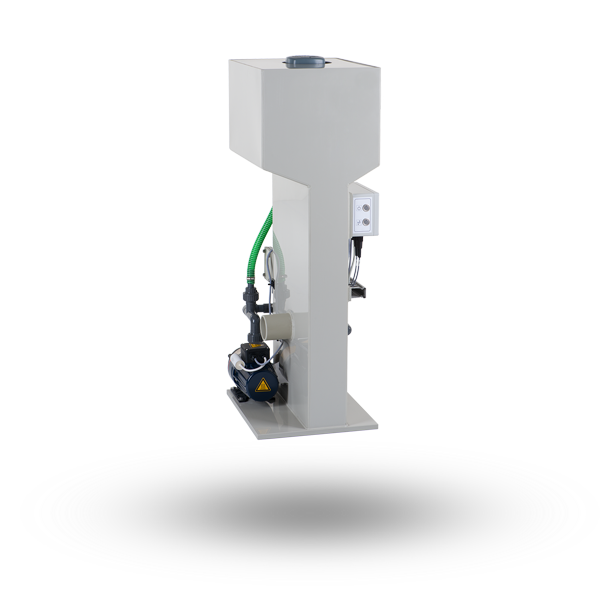

Flexible fume scrubber

The FRIDURIT fume scrubber C20 has been specially designed for the decentralised washing of harmful substances for precise extraction directly at the source. It is equipped with an integrated fan and can be placed anywhere in the room.

Technical data

| Model | Positioning | Air flow (m³/h) | Power consumption (kW) | Water demand (l) | Weight (kg) |

|---|---|---|---|---|---|

| C20 | mobile, stand-alone | 150-200 | 0.4 | 10 | 32 |

| C54 | integration in fume hood | 480-900 | 0.6-1.2 | 45 | 90 |

| C90 | integration in fume hood | 600-1400 | 0.6-1.2 | 60 | 110 |

| C75 | free-standing | 480-750 | 0.6-1.2 | 45 | 90 |

| C180 | free-standing | 600-1.800 | 0.9-1.5 | 70 | 120 |

Special designs and configuration examples

Fume scrubber C180 with neutralisation unit C100

Built into an aluminium stand with locking devices for the free-standing units C180 and C100. The small stand has four adjustable feet, all of which can be adjusted in height to ensure a secure stand.

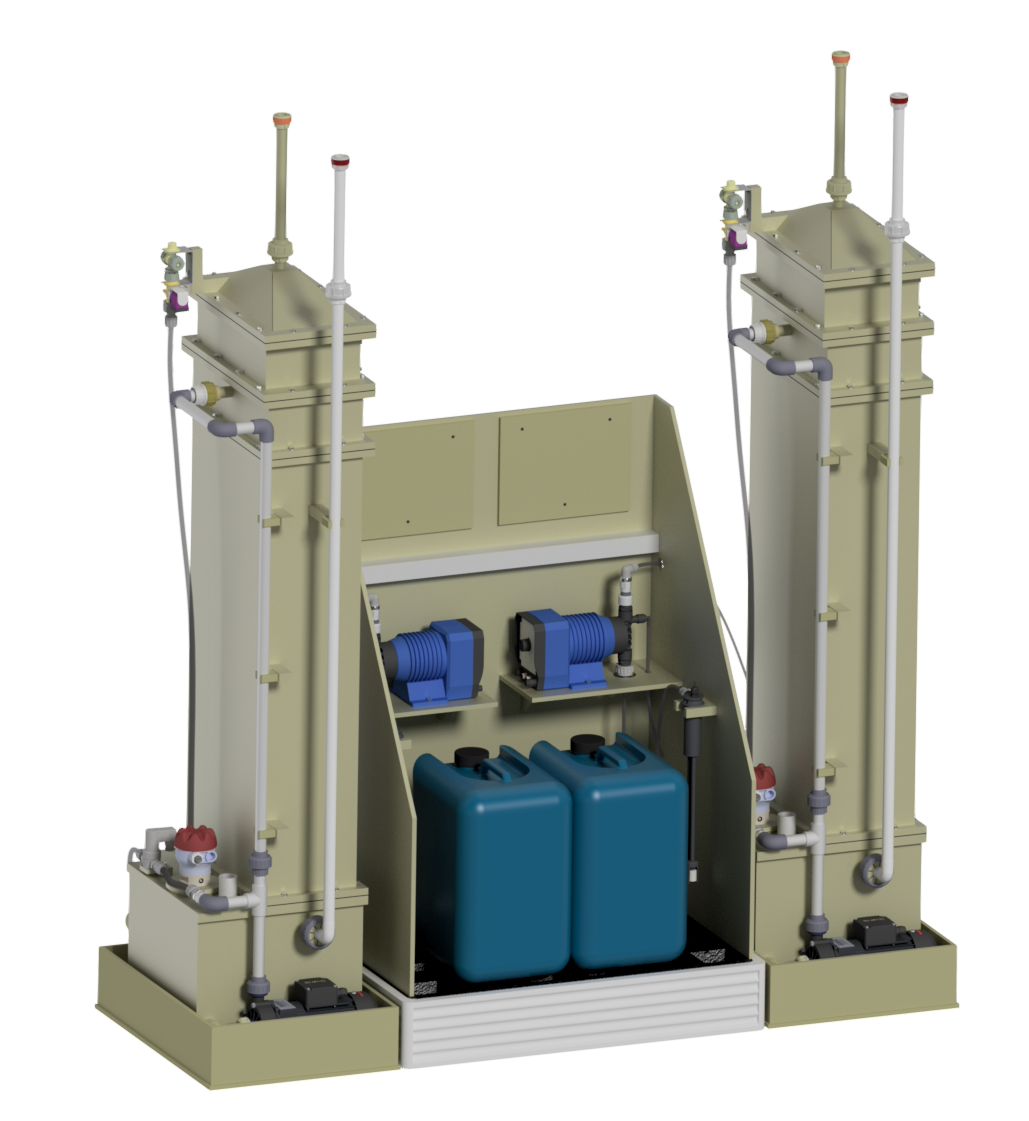

2 fume scrubbers C180 with accessories

Fume scrubber C180 with a special exhaust air duct to expand the line from 1800 m3 / hr to 3000 m3 / hr. However, the two fume scrubbers C180 can also be operated without the special exhaust air duct on this frame. A C100 neutralisation system and a chemical dosing system are also located in the frame. The chemical dosing system is used for pretreating the scrubbing water. The long frame (3600 mm) is made of aluminium with crossbeams and stands on four articulated feet, all of which can be adjusted in height to ensure a secure footing.

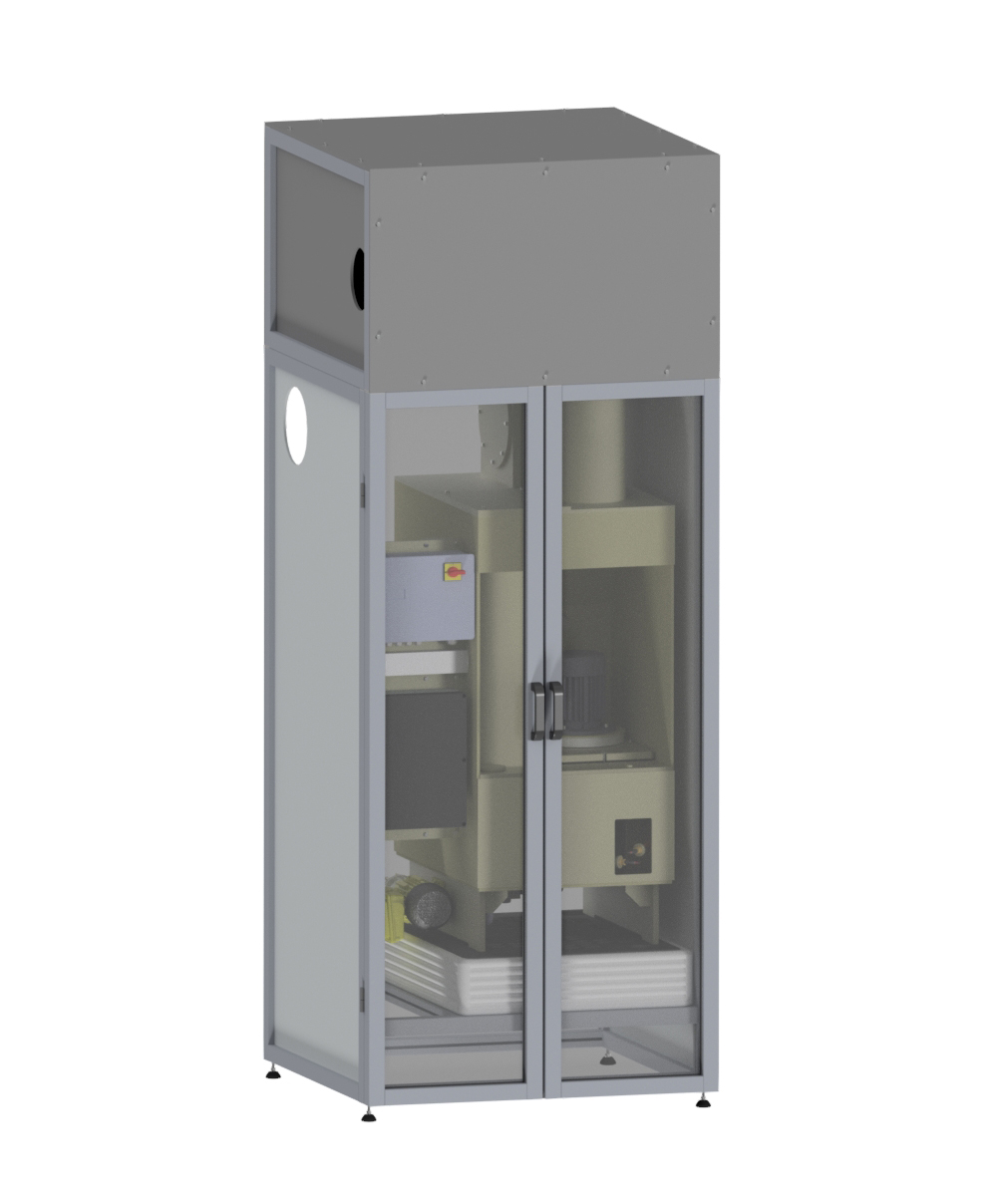

Fume scubber C75 with customised control and pump

Built into a cabinet (900 mm). This cabinet is designed in the standard version to hold an exhaust air scrubber C180 and the neutralisation system C100. In this case, a tall cabinet for the installation of an exhaust air fan was designed on top of the cabinet. The tall cabinet is closed on all sides and sound-insulated. The individual components cabinet, safety tray, exhaust air scrubber C75 and tall cabinet are shipped individually for transport and assembled on site.

2 scrubbing columns in special design

Two fume scrubbers in special design including chemical dosing with diaphragm pump and connecting parts