Lamination technology – a different approach to additive manufacturing

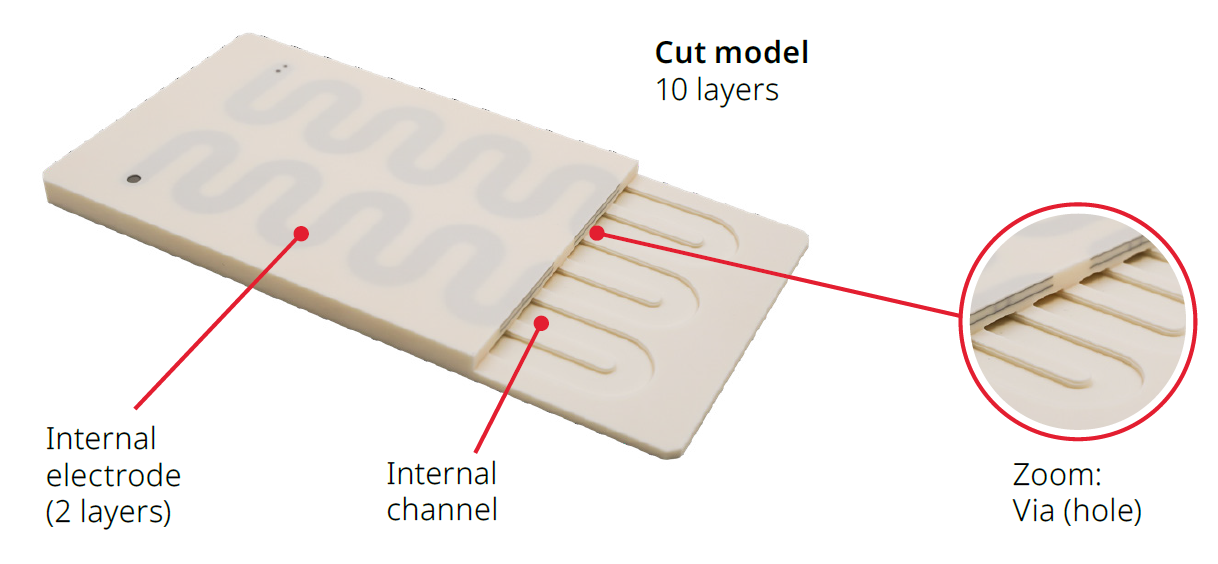

Using a special bonding method several layers of substrates are stacked on each other and form a homogenous ceramic body. The mechanical, thermal and electrical properties of the material are no different from conventionally produced ceramic parts.

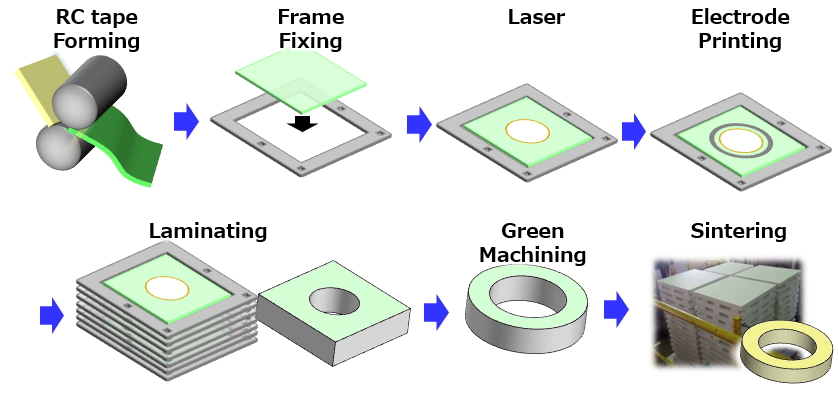

By this (simplified) process flow Kyocera can manufacture complex inner structures, channels and cavities as well as adding intermediate conductive layers for e.g. heating or measurement purposes.

Standard layer thickness and max. size are determined by the material. Several advanced ceramic materials are available for lamination:

Material

| Max size (mm) L x B x Total thickness | Tape thickness (mm)

| |

|---|---|---|---|

| AO479T | 700 x 700 x 30 | 0.6 ~ 1.2 | |

| AO479S | 700 x 700 x 40 | 1.0 | |

| AO579A | 700 x 700 x 40 | 0.5 ~ 1.0 | |

| SC140A | 670 x 700 x 30 | 0.75 ~ 0.85 | |

| CO221O | 670 x 700 x 20 | 1.0 | |

Other materials and dimensions are available upon request.

Typical applications are e.g. handling arms, heat exchanger or trays.

Material characteristics

| Unit | AO476T | AO479T | SC140A | |||

| Colour | - | White | White | Black | ||

| Content | wt% | 96 | 99.6 | - | ||

| Bulk Density | - | 3.7 | 3.9 | 3.1 | ||

| Mechanical Characteristics | Vickers Hardness | GPa | 13.9 | 16.3 | 23 | |

| Flexural Strength (3-point Bending) | MPa | 380 | 470 | 450 (4-point Bending) | ||

| Young's Modulus of Elasticity | GPa | 340 | 380 | 430 | ||

| Poisson's Ratio | - | 0.23 | 0.23 | 0.17 | ||

| Thermal Characteristics | Thermal Conductivity | W/(m-K) | 26 | 30 | 180 | |

| Specific Heat Capacity | J/(g-K) | 0.78 | 0.79 | 0.67 | ||

Coefficient of Linear Thermal Expansion (40-400°C) | ppm/K | 7 | 7.6 | 3.7 | ||

| Electrical Characteristics | Dielectric Strength | kV/mm | 15 | 18 | - | |

| Volume Resistivity | RT | Ω*cm | >1014 | >1014 | - | |

| 300°C | Ω*cm | 1.0 x 1010 | 4.9 x 1010 | - | ||

| 500°C | Ω*cm | 1.1 x 108 | 3.5 x 108 | - | ||

| Dielectric Loss Tangent | 1MHz | 3.0 x 10-4 | 1.0 x 10-4 | - | ||

| Dielectric Constant | 1MHz | 9.6 | 10.2 | - | ||