Silicon infiltrated silicon carbide (SiSiC) – precision and stability under extreme conditions

Silicon-infiltrated silicon carbide (SiSiC) is a high-performance material from the silicon carbide family. Silicon carbides impress with their low weight combined with excellent mechanical and thermal properties and chemical resistance.

Thanks to its dense, homogeneous structure, SiSiC combines high strength, excellent temperature resistance and specific stiffness – ideal prerequisites for use in the most demanding industrial environments, such as the semiconductor industry or aerospace.

Manufacturing process – reaction-bonded high-performance ceramics

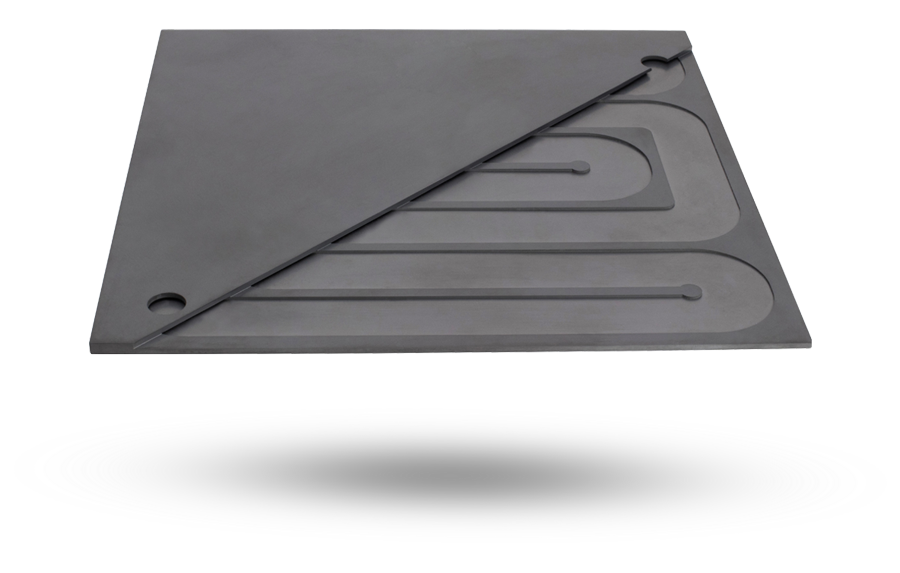

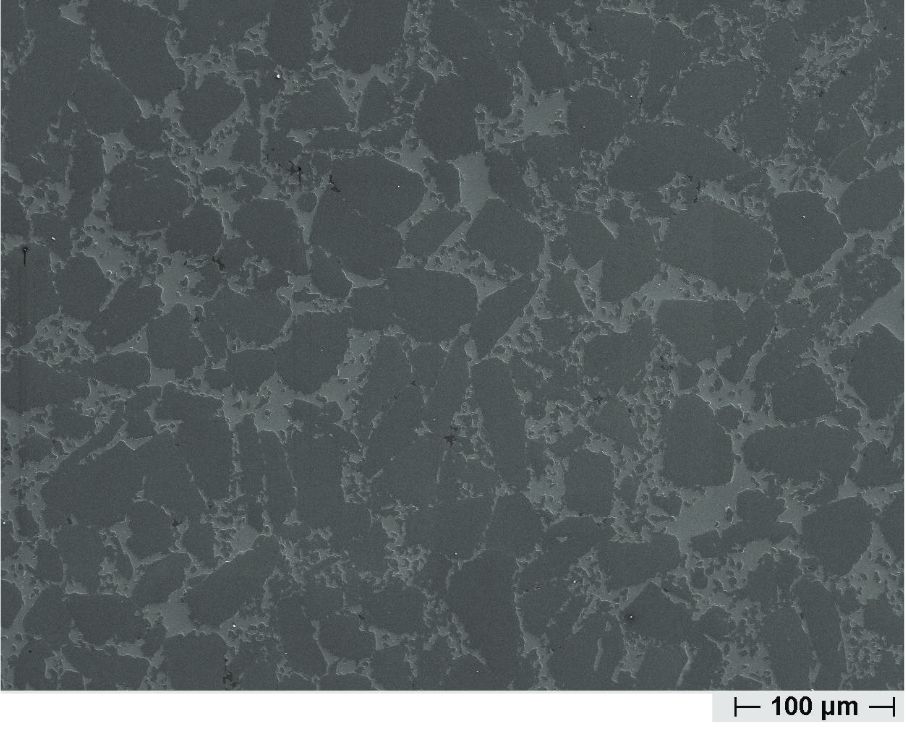

SiSiC is produced with a reaction-bonded sintering process triggered by infiltration. Since SiSiC is shrinkage-free, it can be precisely manufactured to its final contour even in its green state. This allows complex geometries, thin-walled structures and precise fits to be achieved. In the thermal processes, the green body is infiltrated with silicon. The silicon reacts with the carbon contained in the material to form further silicon carbide, and excess silicon remains in the microstructure, ensuring a pore-free structure. The result is a dense, dimensionally stable ceramic that does not shrink and thus achieves exceptionally high dimensional accuracy. Subsequent high-precision machining steps enable precision in the micrometer range, even for large-scale components. Together with the low CTE, this allows components to maintain their dimensions reliably even under extreme loads, such as severe temperature changes or mechanical stress.

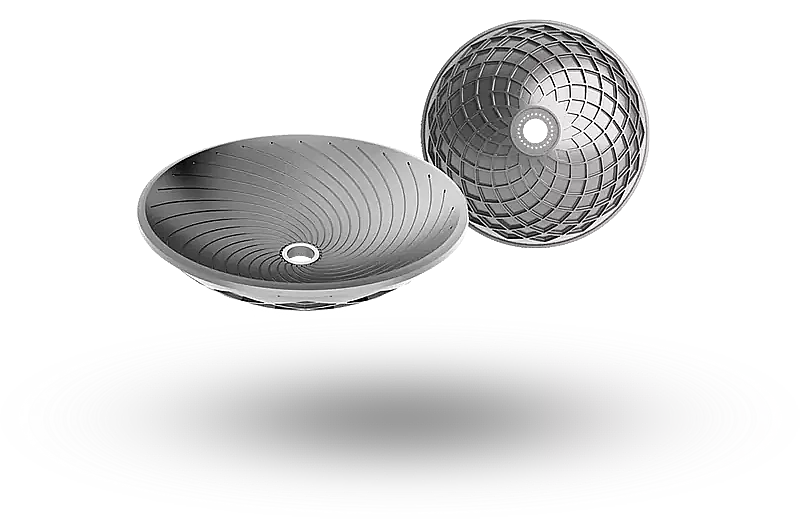

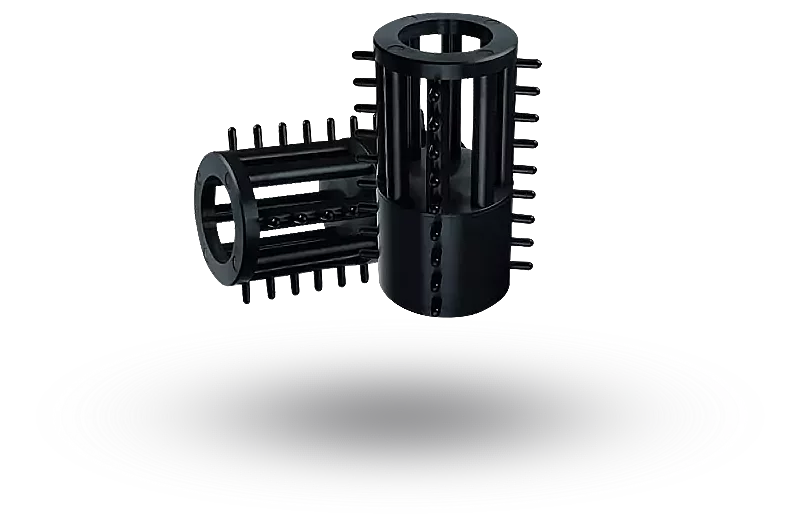

Through skilful component preparation in the green state and process control during sintering, features that cannot be produced conventionally, such as undercuts, cavities or cooling channels, can be manufactured. In addition, the Si content in the structure allows SiSiC to be eroded.

Furthermore, thanks to the possibility of additive manufacturing, there are now virtually no limits to the complexity of the components.

Comprehensive materials expertise at the Selb site

KYOCERA Fineceramics Europe GmbH is the only manufacturer of SiSiC within the KYOCERA Group and is one of the world's largest producers of this class of materials. SiSiC components are manufactured at the Selb site with the highest precision and reproducible quality.

With its extensive expertise, high production capacity and almost complete vertical integration, Kyocera is a leading technology partner in the development and manufacture of SiSiC components.

You are interested in our products, or have a specific project enquiry?

Applications in demanding environments

Its combination of strength, dimensional stability and corrosion resistance makes SiSiC indispensable in a wide range of industries:

Semiconductor industry

Its outstanding mechanical properties, combined with high thermal conductivity, good electrical conductivity and low thermal expansion, make SiSiC the ideal material for a wide range of applications in semiconductor manufacturing. SiSiC is used, for example, as a material for chucks, structural components and end effectors.

Material processing and chemical industry

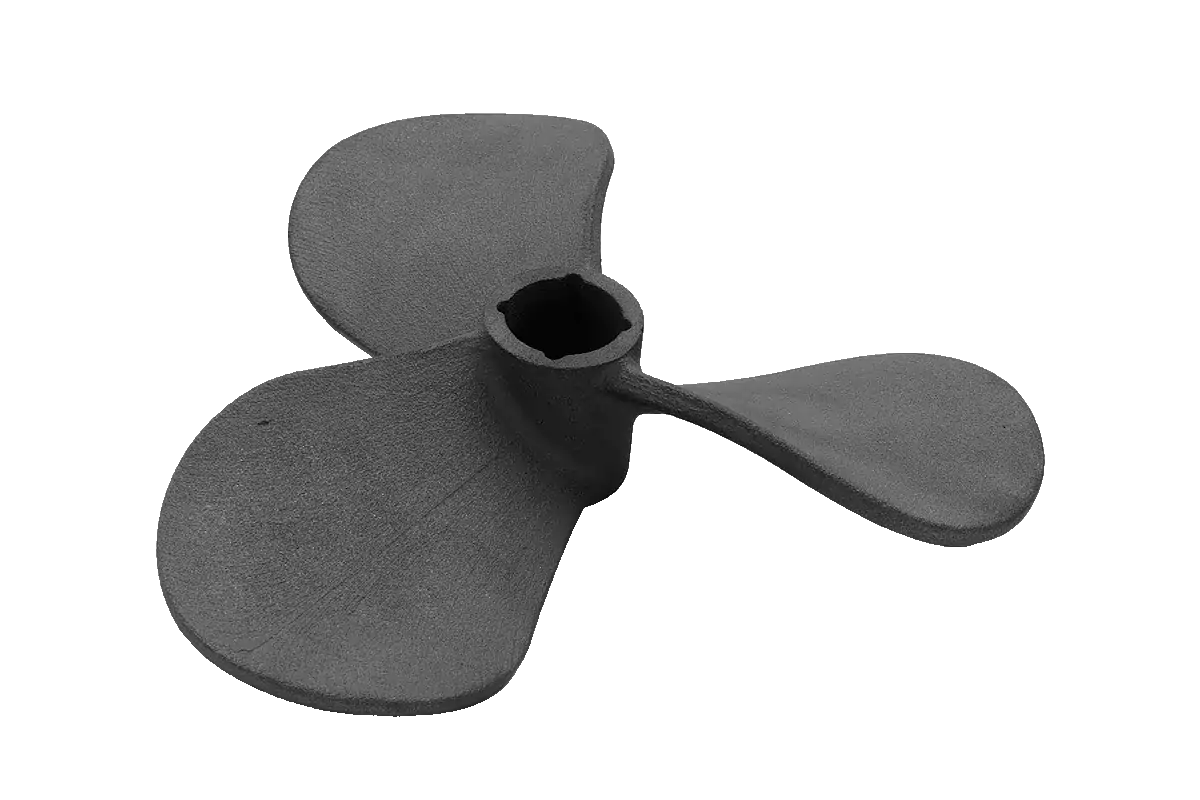

Strength, dimensional stability and chemical resistance make SiSiC a material that can withstand extreme loads in the chemical industry.

In chemical engineering, it is an impressive material for reaction tubes, nozzles, diffusers and carrier plates, for example, which can withstand high pressures and aggressive media.

Energy and environmental technology

In energy and environmental technology, SiSiC is used, for example, in exhaust pipes, heat exchangers and filter housings, where it impresses with its corrosion resistance and thermal stability.

Mechanical engineering

In mechanical engineering, SiSiC also enables heavy-duty bearings, pump parts, mixing and wear components that guarantee a long service life with minimal maintenance.

Automotive industry

The high rigidity, dimensional stability and wear resistance of SiSiC enable reliable components even under continuous thermal and mechanical stress. Typical applications can be found in high-temperature components, wear and structural parts, and in areas where low weight and stable material properties are crucial.

Aerospace

In aerospace, SiSiC impresses with its combination of low weight, high rigidity and thermal shock resistance. The material is suitable for precise, large-scale structural components such as star tracker systems, nozzle systems and mirrors, which require reliable dimensional stability even under extreme environmental conditions.

Comparison of the material properties of SiSiC

| Property | StarCeram® AM-Si (3D printing) | StarCeram® Si |

|---|---|---|

| Density [g/cm3] | 3.00 | 3.05 |

| Flexural strength [MPa] | 190 | 300 |

| Weibull modulus | >10 | >10 |

| Modulus of elasticity [GPa] | 350 | 380 |

| Poisson's ratio | 0.19 | 0.18 |

| Average linear CTE [10⁻⁶/K] (0°-40° C) | 2.3 | 2.3 |

| Thermal conductivity [W/m⋅K] | 185 | 180 |

| Electrical conductivity [10⁻³MS⋅m] | 10 ± 1 | 6 ± 1 |

| SiC content [%] | >75 | >85 |

| Typical colour | grey | grey |

SiSiC or SSiC?

| Property | SiSiC | SSiC |

|---|---|---|

| Erodible | yes | no |

| Additive manufacturing | yes | no |

| Shrinkage | no | yes |

| Component size | very large | large |

| Laser structuring | yes | yes |

| Joining to monolithic components | yes | no |

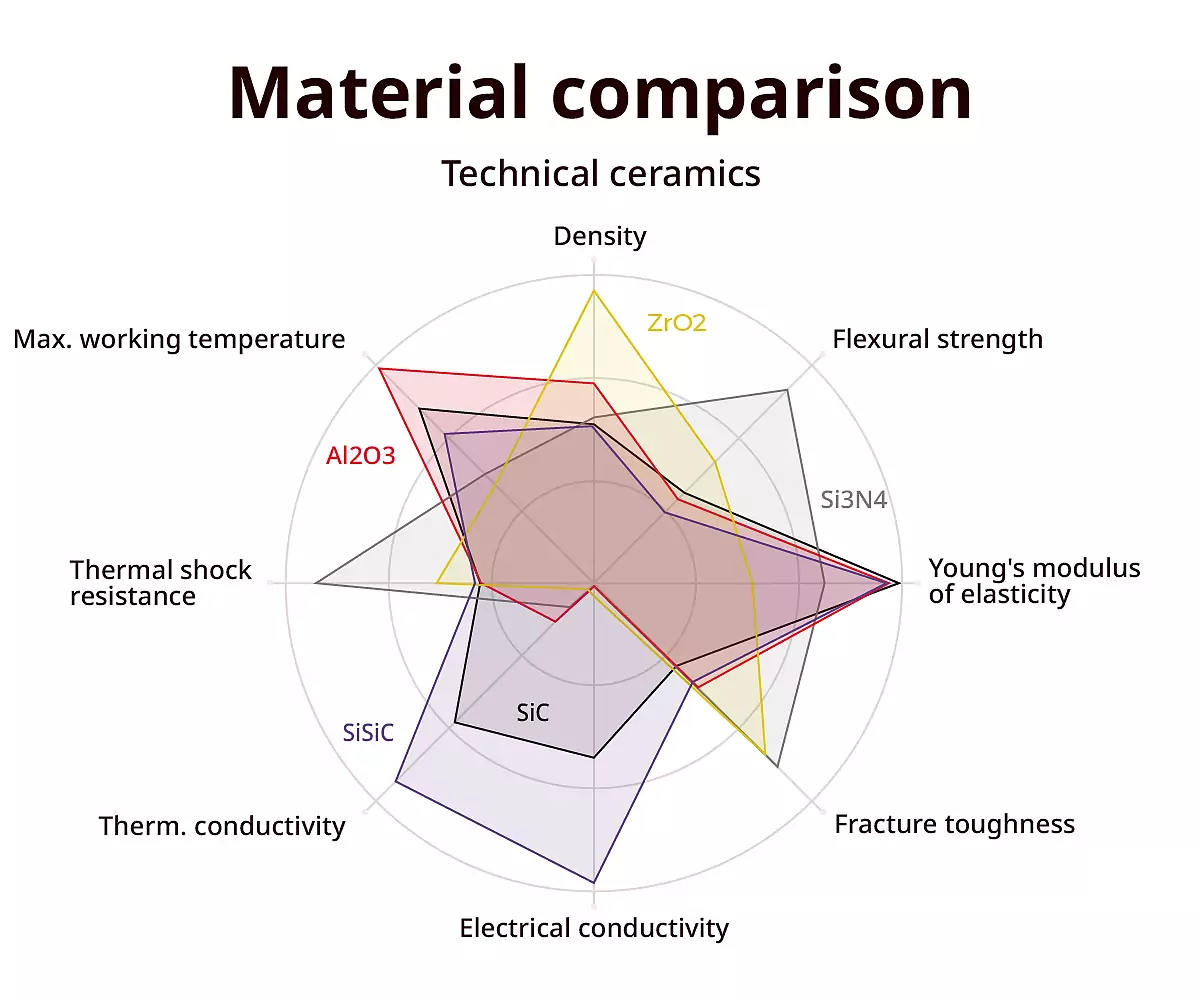

Properties of SiSiC compared to other ceramic materials

FAQ

The main difference lies in the manufacturing process: SSiC is densely sintered, while SiSiC is reaction-bonded and infiltrated. This means that SiSiC contains a proportion of free silicon, making it more dimensionally stable and more resistant to breakage – ideal for large-volume or complex components.

Depending on component complexity and requirements, SiSiC can also offer a significant economic advantage, which can be further increased by 3D printing, especially in terms of operating costs.

Compared to metals, SiSiC offers numerous technical advantages:

- Lower density: approx. 3 g/cm³ – only one third of the weight of steel.

- Higher hardness and wear resistance: no abrasion with abrasive media.

- Excellent corrosion and oxidation resistance.

- Temperature stability: no plastic deformation under thermal loads.

- Longer service life: less maintenance, lower operating costs.

SiSiC remains dimensionally stable and oxidation-resistant up to approximately 1,350 °C. SSiC is recommended for applications above 1,400 °C.

The reaction-bonded manufacturing process prevents sintering shrinkage – the components remain dimensionally stable and distortion-free, even with large geometries.