The right solution for every requirement

Maximum performance and reliability

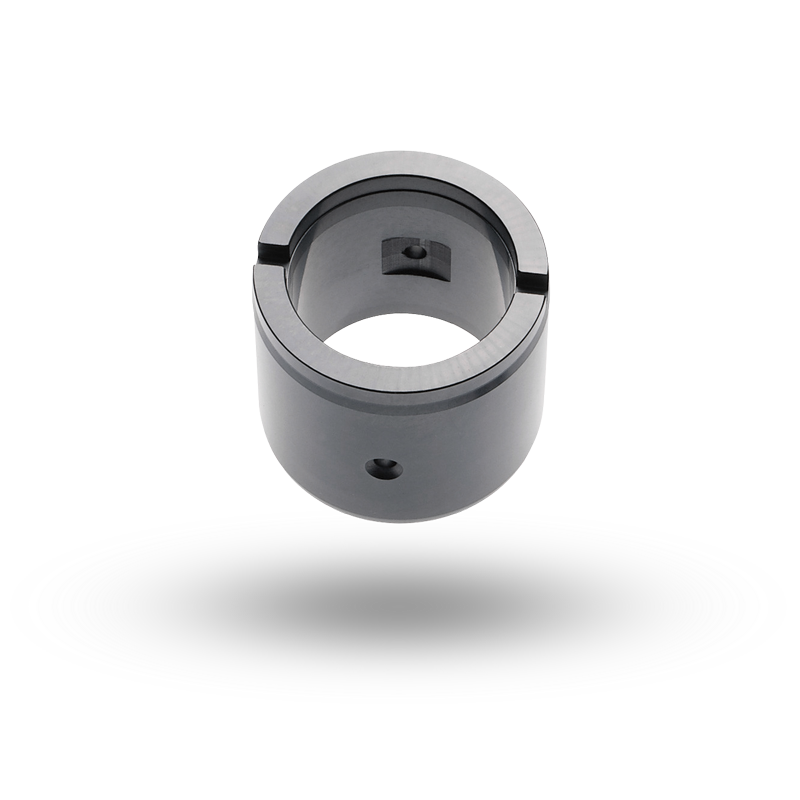

Cylinder linings are an essential part of many applications and machines, including extrusion and injection moulding cylinders, as well as in ore mining. To ensure maximum efficiency and long service life, they must withstand various stresses, including wear, corrosion, and high temperatures. This is where Kyocera's technical ceramic cylinder liners come into play.

Wear-protected surfaces

Our cylinder liners are characterised by their high hardness and strength, contributing to excellent wear protection. This makes them ideal for applications that are subject to high stresses.

Low adhesion

The low adhesion of the ceramics ensures that no materials accumulate on the surface and, therefore, no contamination occurs. This improves the efficiency and availability of the machine.

Reduced wall friction

The reduced wall friction leads to a lower energy loss and, thus, to higher machine efficiency.

High hardness

The high hardness of the cylinder linings guarantees a long service life and reliable performance.

Low weight

Thanks to their low weight, cylinder linings made of advanced ceramics are particularly suitable for applications where weight plays a decisive role.

We offer cylinder linings made of silicon nitride, silicon carbide or alumina to meet your individual needs and requirements. We proudly offer you a wide range of solutions tailored to your specific needs. Contact us today to work together to find the right solution for your applications.