THE RIGHT SOLUTION FOR EVERY REQUIREMENT

Advanced ceramics in semiconductor manufacturing

Wafer chucks, chuck supports and other components for wafer tables are essential for semiconductor manufacturing. Our technical ceramic components offer first-class solutions for your demanding requirements.

The excellent specific rigidity of our high-performance ceramics ensures precise positioning and complete stability in your manufacturing processes. The high thermal conductivity combined with the very low coefficient of thermal expansion (CTE) minimises the effects of temperature variations in your processes and contributes to the stable performance of your equipment. Furthermore, technical ceramics convince with their high wear resistance and low weight.

Trust Kyocera wafer table components to optimise your semiconductor production and make your processes more efficient. Discover the future of semiconductor technology with our technical ceramics.

We support you in the selection of materials according to your requirements: Silicon Carbide (SiC), Silicon Infiltrated Silicon Carbide (SiSiC) and Silicon Nitride (SiN). Both SiC and SiSiC can be additionally provided with a SiC coating. Due to the unique process, these coatings achieve impurities of well below 3 ppm. This enables applications in particularly sensitive process environments. The adhesion of the coatings allow multiple coating and deep hole coverage. This enables applications in extreme high vacuum and complex designs for special processes.

You are interested in our products or have a specific project enquiry?

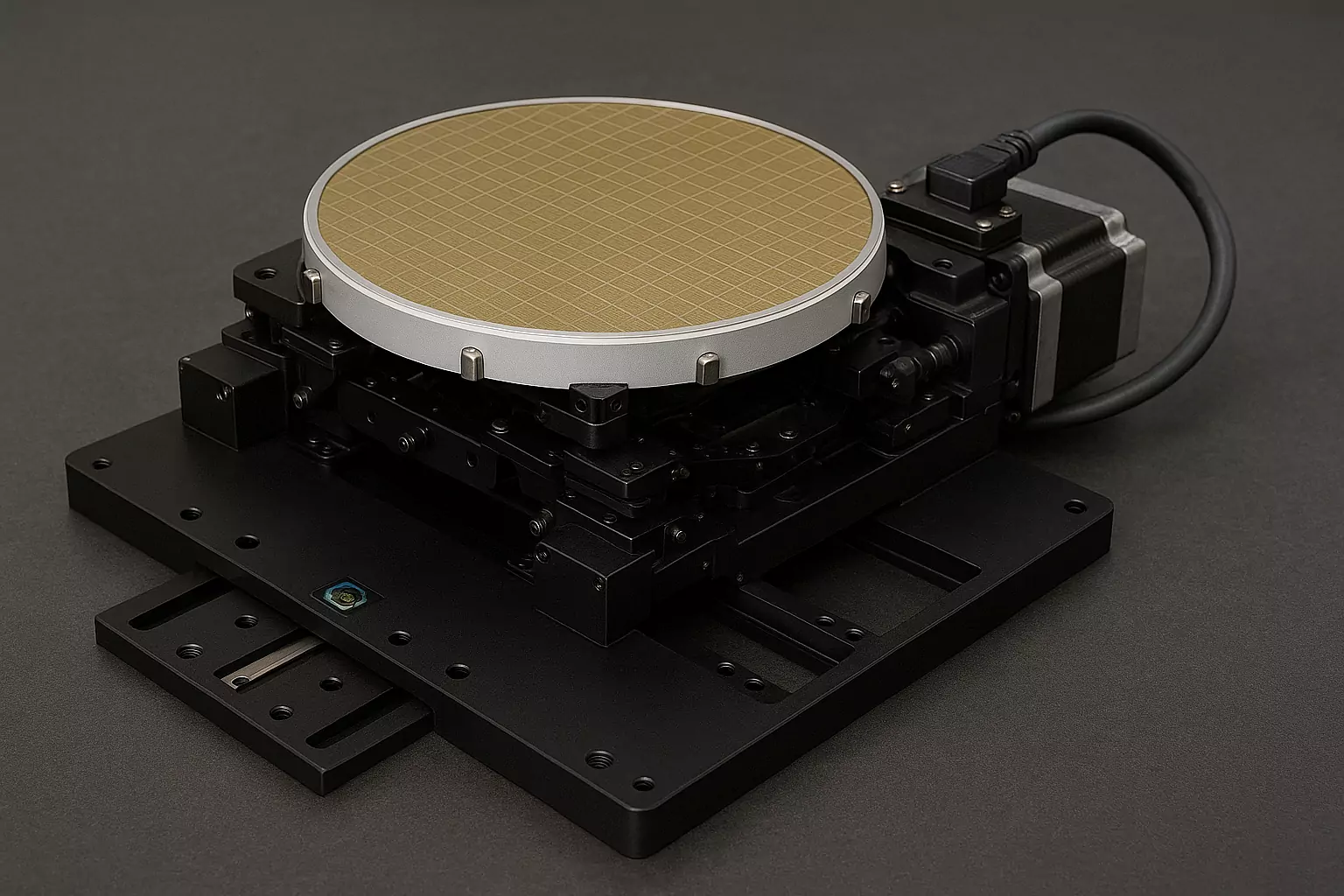

Components for Wafer Tables: Product Overview

We offer a wide range of components for wafer tables. From chucks to chuck supports to guide rails. Together with our customers, we find the right solution for every requirement.

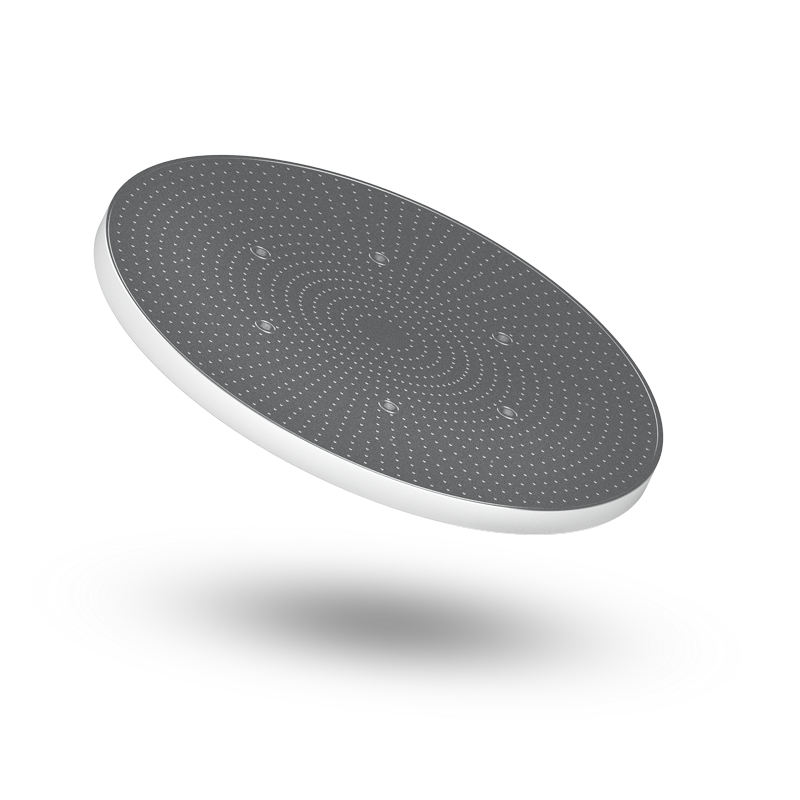

Wafer Chucks

Our portfolio includes vacuum chucks, electrostatic chucks (ESC) and susceptors to meet your specific requirements.

Our vacuum chucks provide reliable fixation of your wafers and ensure precise positioning during processing. They are ideal for applications where high stability and precise alignment are required.

ESC offer an innovative solution for demanding processes in vacuum. They allow wafers to be fixed with the highest precision.

In addition, our susceptors offer the possibility of using high-precision components in your production.

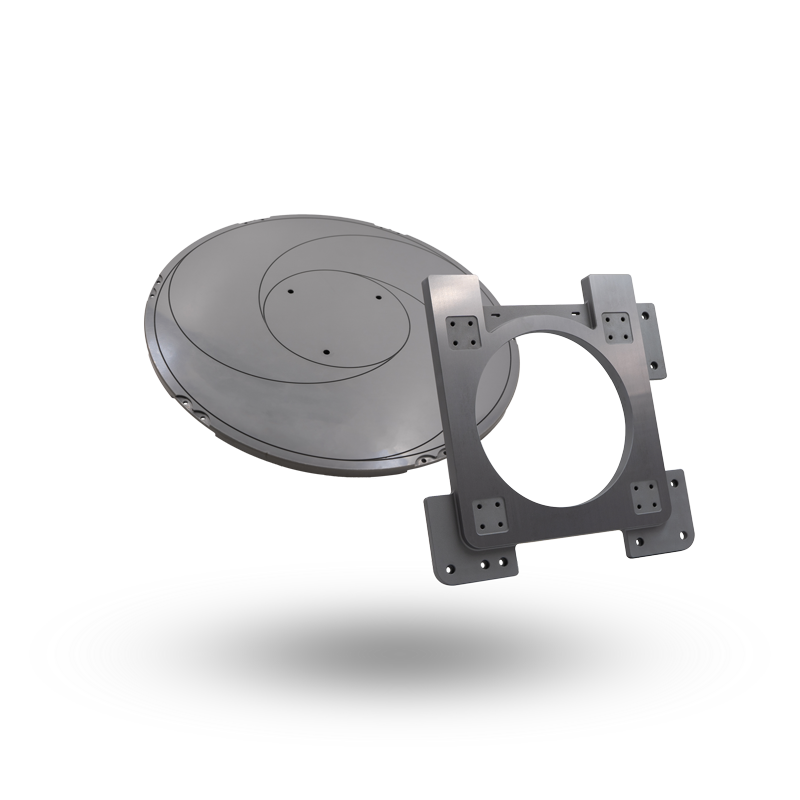

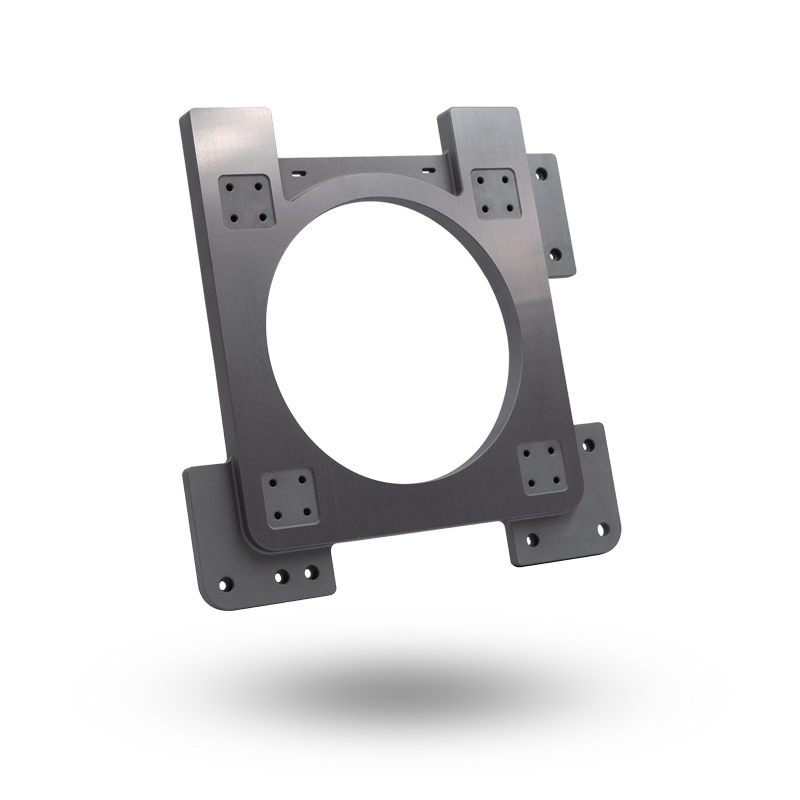

Chuck Support

The high-precision machining of our ceramics and the remarkable specific rigidity enables the production of very complex components for wafer tables.

The polishing and coating capabilities of our ceramics with optical materials such as aluminium also enable their use in optically controlled equipment.

Further components for wafer tables

The very high precision, even for large monolithic components larger than 1 m, brings further advantages in the design and possibilities for guide bars, sliders, encoders and many other components.

The advantages of Kyocera's manufacturing technologies and the excellent properties of our ceramics enable the cost-effective realisation of components and assemblies for which other materials were previously considered.